Numerous logistics leaders view digitization as the need of the hour. Yet, the primary steps to developing the general strategy are unclear. Here, we delve into the questions of the state of digital transformation and take a stab at unravelling different versions across the logistics industry.

Important questions include:

In this article, we’ll address these questions with insights derived from research conducted by a variety of logistics firms.

What is Digital supply chain?

While the term digital supply chain is widely used, there’s little agreement on what it means. There are various responses from leaders across the logistics industry that incorporate the following factors:

From these and other similar responses, we found a unifying thread to define the digital supply chain: A digital supply chain makes maximum use of “digital” technologies to plan and execute transactions, communications, and actions.

Embedded within this definition are fundamental notions of dematerialization, automation, and AI. Within the following sections, we describe the important core attributes and digital technologies that are defining and driving digital supply chain transformation.

A core attributes model

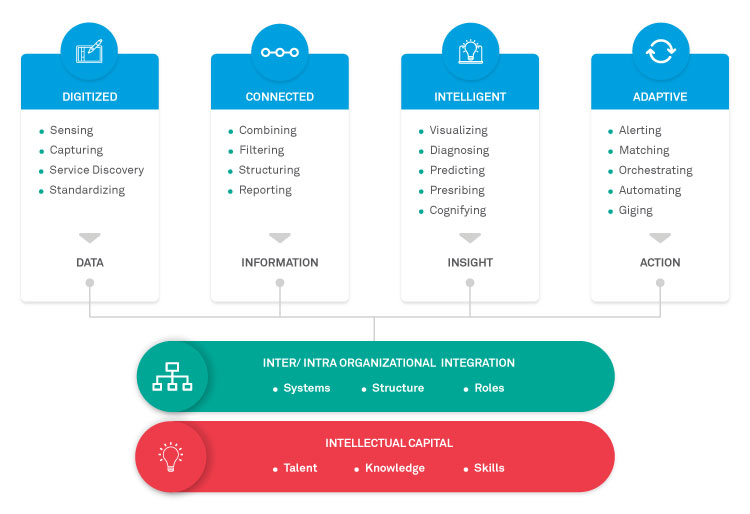

Digital supply chains sense, analyze, predict, and answer to changes within the operating environment. Essentially, this suggests that supply chains use technologies, organizational structures, and skills to capture data, convert it into information, analyze it, and adapt to it far more quickly, accurately, and specifically than conventional supply chains could ever do. The figure below illustrates these core digital supply chain attributes.

1.Digitized. It all begins with data. The first virtue of a digital supply chain is that it reduces uncertainty by providing current, accurate, complete, and useful data. While supply chain managers have access to lots of information today, typically only a little fraction meets these criteria. Accordingly, getting data that has strategic value as a useful form is often an enormous initiative toward digital maturity.

We believe that the goals for several leading industry firms are to:

2. Connected. Digital supply chains convert data into information and convey it to stakeholders and decision-makers in a timely fashion. Information is shaped when data is combined, filtered, and arranged in useful ways. Many supply chain managers complain that they’re awash in data but lacking in information. The aim to form information available to the correct people at the proper time is a crucial digital supply chain goal.

3.Intelligent. A digital supply chain also provides insights and intelligence, beyond merely summarizing and organizing data. This needs applying analytics to diagnose situations and events, using algorithms to predict possible outcomes and risk assessments, and prescribing courses of action with possible alternatives. The digital supply chain needs to:

4.Adaptive. The last core attribute of a digital supply chain is adaptability—the ability to act on resulting insights. This attribute is least commonly related to digital, but it likely has the best impact on performance. Predictions from analysis are most accurate within the short term. Thus, to understand the complete value of a digital supply chain, it must be ready to quickly respond and act upon the intelligence it creates.

Several of the leaders identified responsiveness as a crucial goal of their digitization efforts using statements such as:

For many firms that are starting the digitization journey, a vital question is: Which of the attributes presents the major obstacle or opportunity?

Enabling Technologies

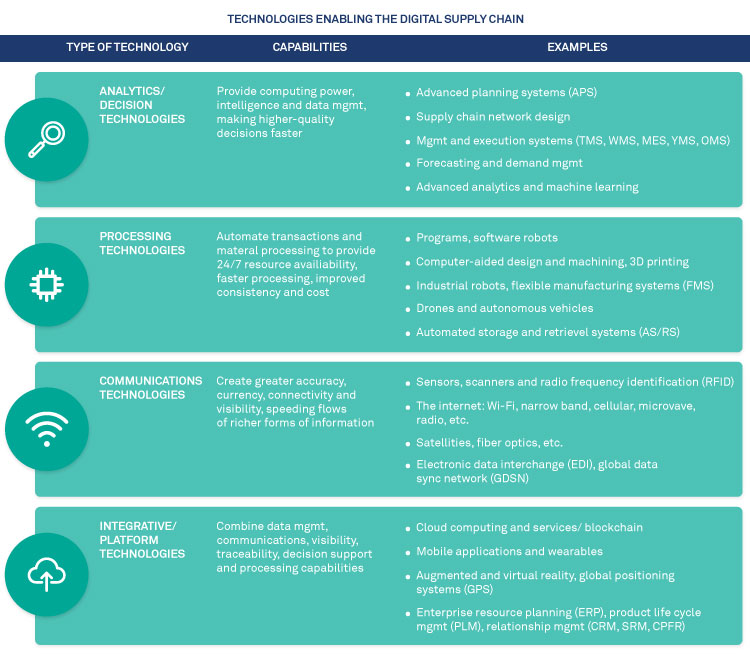

There are numerous samples of technology applications in supply chain processes, including artificial intelligence (AI), robotics and predictive analytics. The table below groups enabling technologies along with their primary purpose and capabilities. Many logistics leaders indicated that keeping pace with technology was a key challenge, highlighting the importance of working with excellent partners to gauge, select, and develop solutions. Equally important, we foresee the necessity for a bigger view of integration across technologies, owing to the boundaries of existing systems.

Technology adoption and enablement is clearly an important and vast topic and a significant differentiator in the maturity of digital supply chains. We strongly suggest that leaders should focus on linking the core capabilities of technologies with business-level strategies, instead of simply focusing on solutions to problems.

State of digital transformation

Researchers examined the journey that companies are taking in their digital transformation; determining where they are along the trail, and whether or not they have precise goals and a roadmap. One key finding: In a world crammed with hyperbole and up-to-the-minute stories of technological advancements, the truth is that the majority firms, even leading ones, aren’t that far along with digital transformation.

What does maturity look like?

One could consider overall digital transformation maturity as the degree to which a firm applies enabling technologies in ways which provide the core attributes (digitized, connected, intelligent, adaptive). However, supply chain “transformation” implies something bigger than applying specific technology “solutions” to localized problems. Answers to the subsequent questions provide a snapshot on maturity:

Stage of Implementation

We found significant variation in levels of investment and stages of digital transformation among various firms. Industries vary, especially in terms of technology investments.

The following statements summarize the positions of many of the firms.

Despite the hype, just a handful of even the most advanced firms have yet to add advanced analytics or intelligence like machine learning into to their digital transformation journeys. Most are focused on the initial steps of digitizing data and connecting stakeholders in ways that provide greater process visibility, and on automating transactions and data translations needed to smooth information flows. Additionally, several firms are somewhat opportunistically applying technologies like 3-D printing and robotic process automation (RPA) to scale back capital (inventory) and labor costs.

Enables and challenges

Where today, data analysts are playing increasingly important roles within the development and use of analytics that make diagnoses and predictions; tomorrow’s systems would require a more general set of skills, including business domain knowledge, to properly interpret and apply prescriptions made by increasingly intelligent software agents. Other challenges include:

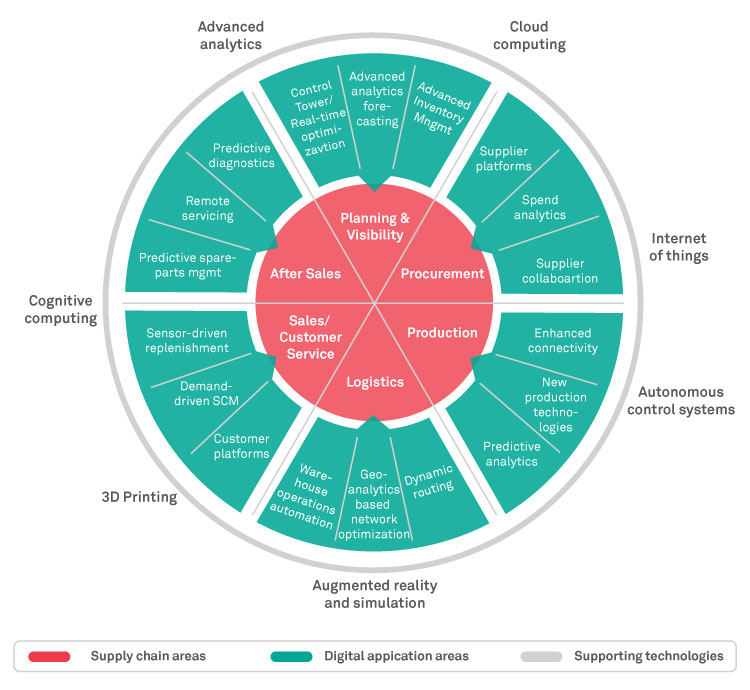

The figure below provides a holistic view of areas of opportunity for digital transformation

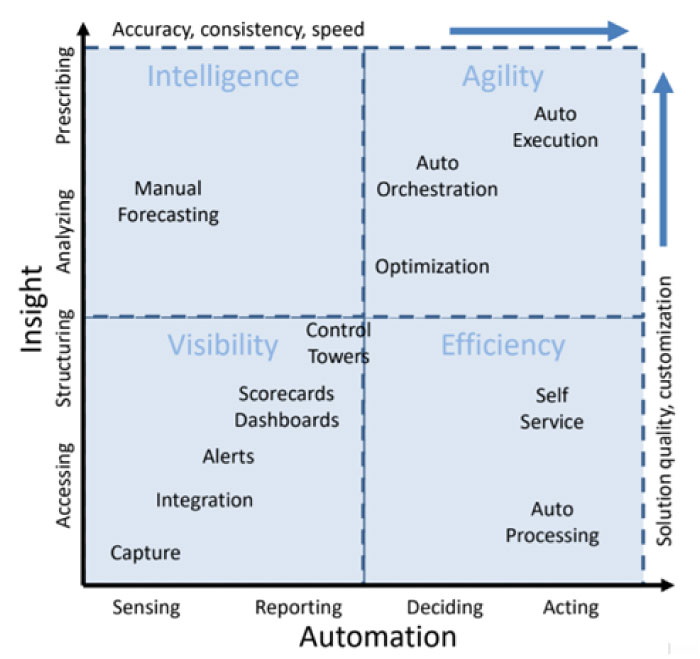

Recommendation: Build capabilities

A good roadmap ensures a variety of projects for a transformation portfolio and is formed by the precise strategies and competencies of the firm. Each roadmap is going to be unique because it matches its unique circumstances. Even so, we believe it’s valuable for all to retain certain essential capabilities in view, as they run through the details of transformation plans.

We map these capabilities along two core dimensions of technology enablement: automation and insight. Many technologies automate decisions and actions, including computations, transactions, data capture, physical transformations and movements, and more. Automation substitutes capital for labor in ways in which it improves efficiency and quality by lowering costs, speeding-up processing and transitions, improving consistency, and increasing resource availability. Technologies that improve insight increase visibility and intelligence by connecting stakeholders, structuring and sharing information, and cognifying processes, that is, developing knowledge through analysis and learning. In its most essential form, digital transformation is about developing automation and insight to radically advance visibility, intelligence, efficiency, and customer experience and agility, as well as customization.

Visibility

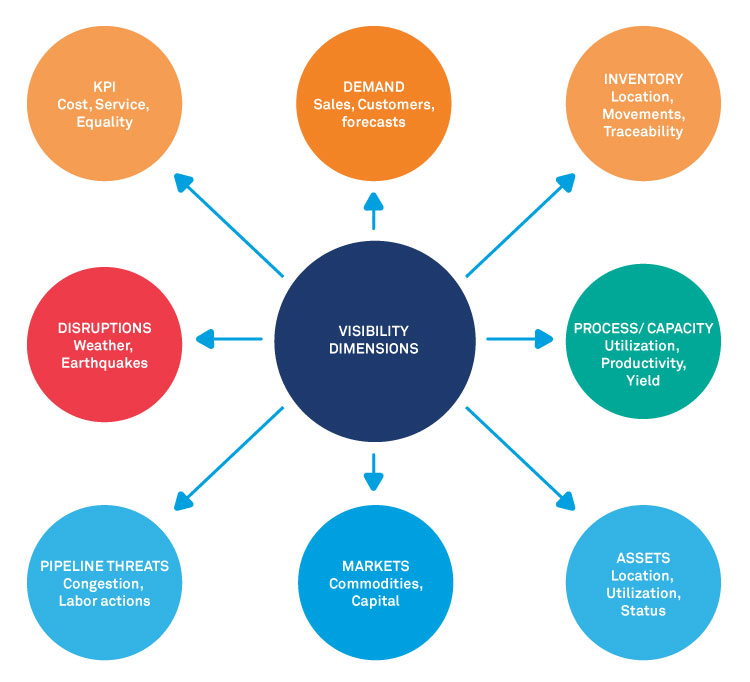

Visibility means having the data you need at the time you need it. Good information comes from data that is current, accurate, complete, and usefully formatted. As discussed earlier, visibility requires digitization and connectivity for the processes and stakeholders involved. Typically, this suggests visibility that reduces or eliminates the foremost damaging uncertainties within the logistics, and/or visibility that offers the maximum potential for improvement and competitive advantage. Almost by definition, developing visibility requires working with upstream and downstream partners to develop data standards, alongside technologies for data capture and connectivity.

Intelligence

Visibility lays the groundwork for next-level insights enabled by applying intelligent algorithms to visible data. Smart programs using machine learning and other sorts of AI can provide a deeper understanding of trends, anomalies, and even causes of process effects. These technologies also tend to be useful when applied to repeated processes that produce massive amounts of data like sales, clickstreams, asset monitoring, and other transactions. Levels of intelligence include visualization, analytics, prediction, and prescription.

Efficiency and customer experience

New technological capabilities go far beyond the essential benefits of greater efficiency. Automation now means better speed, quality, and improved user interactions. In manufacturing, emerging examples illustrate the super-productivity of robots and humans working side-by-side—known as cobots— arrangements that are more productive than either robots or humans working alone. In services, automation is improving interactions between service providers and customers, as well as between supply chain partners.

Agility and customization

The holy grail of digital transformation is agility— the ability to quickly and efficiently adapt supply chain capacity and resources to satisfy changing conditions. Though most companies are converging on efficiency, some are developing visions of agility and customization. At the very best levels of maturity, firms will apply automation and insight to develop systems that both predict and adapt to changes, including shifts in demand, disruptions, environmental and regulatory changes, and competitors’ maneuvers.

Many monikers have been used to describe this capability, including on-demand, uberized, mass-customized, and responsive. Essentially, this suggests breaking constraints and unfixing capacities within the supply chain, moving to variable cost structures and building flexibilities that enable rapid scalability, supply-demand matching, seamless transitions, and changeovers, increased operating range, optimal re-routing, and dynamic sourcing.

Final Thoughts

This article synthesizes the insights garnered from research spanning a good range of logistics companies. We trust that the outlines and answers offered here will stimulate ideas and foster new ways of visualizing possibilities in digital transformation journeys. Few firms appear to be far down the trail toward maturity, but the stories and examples we uncovered promise an exciting future for the logistics domain. It is likely that, given the massive turbulence in technologies, geopolitics, and economics over this period, many executives are wary of making big investments; they are waiting for the uncertainties caused due to COVID-19 to stabilize. The new normal is an operating environment full of unresolved and continuing uncertainty. Consequently, the future will belong to organizations that advance toward more digitized, connected, intelligent, adaptive models, ensuing well-thought-out, and agile roadmaps for digital transformation.

References

Contact us for a deep dive and expert consultation on your digital transformation journey