Process Monitors power up insights for continuous improvement on shop floors

Process Manufacturing industries are married to data. Not surprisingly, they have remained deeply faithful to the practice of collecting and using operational data. Over the years, their faith has helped decode complex plant processes and correct aberrations in quality. Six Sigma, Lean, Kaizen, etc., are some of the tools used with data to drive quality improvement. The focus of improvement is not misplaced. Analytics in operations has the potential to add millions of dollars to bottom lines by optimizing yield, reducing energy consumption, refining product quality and improving machine/equipment utilization. However, despite these substantial investments, the industry faces a grim challenge when it comes to driving continuous improvement.

Why is continuous improvement so critical?

To fully grasp the significance of continuous improvement, a simple example serves the purpose. Take the Flight Data Recorder (we know it as the Black Box) in a commercial aircraft. The Black Box is the go-to device in the event of a disaster. Flight operations data can reveal what happened to the aircraft. Operational analytics in process manufacturing is identical. When a process parameter in manufacturing goes rogue, everyone goes hunting for data to analyze.

What if the aircraft’s Black Box could send data back for real-time analytics? This would help create interventions before anything unfortunate happened. Process manufacturing is no different. Using real-time analytics, it can proactively offer insights for continuous improvement. Some Smart Factories that are forging the future of manufacturing are already doing this. They use Wipro’s Process Monitor to make continuous improvement a reality.

Process Manufacturing stalwarts know the importance of reducing variability across plants, manufacturing lines and runs. Their Manufacturing Execution Systems (MES), process data historians, Laboratory Information Systems

(LIMS) and Enterprise Resource Planning (ERP) systems automatically generate and stockpile terabytes of data to achieve just that. But the data is unwieldy. Different systems, processes and equipment generate it. Besides, data acquires different business definitions and names depending on the plant that generates it. All said and done, the process of unifying and looking into the data is a nightmare.

This means that when the data arrives, end-users such as shop floor operators, maintenance teams, scientists and engineers are unable to use it quickly and effectively. The problem is compounded when analytics is applied on the data in real time. And, real time is the key to continuous improvement.

The Process Monitor overcomes these challenges. The tool allows manufacturers to perform the analysis as the manufacturing event is happening and takes pre-emptive corrective action. In reliability circles, this is referred to as on-condition monitoring or predictive maintenance and it applies equally to all failures that affect manufacturing quality, throughput and safety.

Recently, Wipro applied the Process Monitor in combination with ManufacSURETM Analytics to solve a quality problem known as ‘surface defects’ for a major steel manufacturer. While the manufacturer took more than three months to wade through oceans of plant data looking for the troublesome parameters, the Process Monitor did it in just a few days. And, to arrive at the same diagnosis in only a few minutes, the system has now been automated.

Maintaining product quality, irrespective of the industry type, is not an option anymore. It is a necessity.

At one high-speed film coating facility, the Process Monitor reduced run-to-run variability in a coating solution. This allowed engineers to optimize the formulation by lowering the amount of a high cost material, resulting in a $500,000 saving per year on just one product.

The implementation of Process Monitor at a global chemical manufacturing company, on the other hand, resulted in the successful root cause analysis of quality problems, reductions in run-to-run variability, optimization of recipes, increased First Pass Yield, non-standard downtime reductions and throughput gains. Aggregate savings ranged between $5 million and $7 million per year across the company. Implementations have shown that the Process Monitor provides 2-4 times return on investments.

Process Monitor in action

Process Monitor is a standardized shop floor tool for engineers and operation teams. It contains many analysis functions and displays results in standard Statistical Process Control (SPC) charts. In other words, it standardizes data, allowing Yield Analytics to reduce the massive data sets to a critical few that are essential to the shop floor.

How Process Monitor works

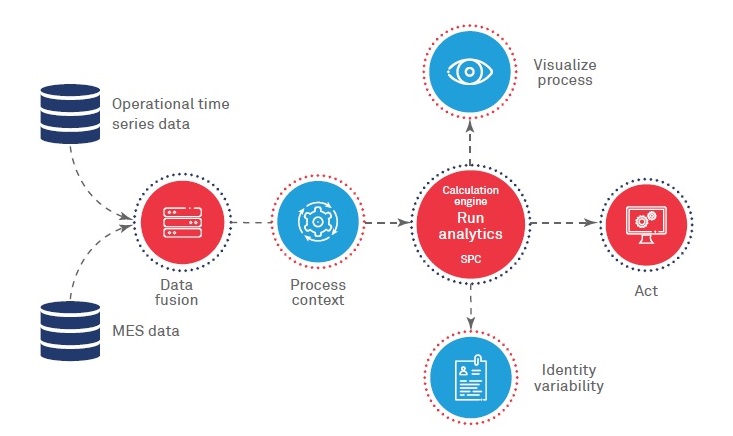

Process Monitor uses SPC charts, powerful calculating functions and models that allow users to visualize variability in process from one production run to the next. This allows operations to immediately investigate the root causes of variability, machine breakdowns, waste, etc., and then act to drive consistency and improvement across runs (see above how ProcessMonitor works).

Real-time plant operation data flows into plant applications (Historian, LIMS, PLC, DCS etc.) and is combined with plant analysis data (ERP, APS). This, then, is sent to the Process Monitor, which uses real-time, order-based, context-sensitive control charts linked to their underlying time series data, over 500 analysis functions and the multivariate algorithms to summarize vast numbers of control charts.

Advanced users can exploit cutting-edge analytics, including multivariate algorithms, to view variability across all control charts and to correlate to product quality response variables.

Taking charge of operations

The visualization layer sheds light on operations and asset performance. This is a boon for plant operation engineers who can confidently answer baffling questions such as:

For skilled and experienced technical professionals, the Process Monitor’s allure lies in its ability to deliver breakthrough improvements. As the Internet of Things multiplies the volume and type of data available to process manufacturers, the Process Monitor adds to their capability to steer production towards better value.

John Joseph Scheible - Consulting Partner, Smart Manufacturing solutions group at Wipro - He is an expert in continuous improvement in manufacturing and in commercialization programs. He co-developed the Process Monitor application and drove its usage across global sites as part of Eastman Kodak, from where he joined Wipro earlier this year.

John is a certified Six Sigma Black Belt with degrees in Chemical Engineering and holds US patents in analytics and chemical applications.

Paul Turner - Principal Consulting Partner for Advanced Manufacturing Analytics Practice at Wipro - He has extensive experience in driving value through the application of advanced analytics to manufacturing processes. He has over 40 publications, including multiple patents in the field of process optimization, artificial intelligence and analytics.

Paul is a chartered engineer and has a Ph.D in manufacturing analytics.