The Manufacturing industry is realizing benefits of mobile applications in driving productivity and optimization, reducing costs, improving efficiencies and enabling better field service, however, compared to other industries, enterprise mobility is not the top priority for most executives in the manufacturing sector.

This paper discusses the various applications of mobility in manufacturing and how industry players must adopt a structured mobile strategy to maximize their RoI on mobility.

Introduction

The last three decades have seen a tremendous increase in global digital connectivity and ubiquity. Sample this: a traditional ‘mobile terminal’ costs thousands of dollars, has proprietary (and expensive) mobile middleware, a non-existent developer eco-system and a limited partner eco-system making it diffi cult for IT execs to justify RoI.

Advances in enterprise –mobile solutions – such as mobile device management, enterprise mobility middleware, mobile application development tools as well as sophisticated lower cost consumer devices – have significantly reduced the entry barrier to implement enterprise mobile applications.

In a survey conducted by Wipro and TLG, business leaders see mobile platforms as important tools to engage employees, customers and partners to help shape products, improve service delivery and spur innovation.

A similar survey by Motorola on the effects of mobile tech on manufacturing productivity found that “manufacturers with mobile applications saved a daily average of 42 minutes per employee,” as reported by CIMx. Furthermore, approximately 70 percent of IT managers in manufacturing were attempting to introduce mobile and wireless applications into day-to-day operations to improve efficiency.

With such evident benefits and enthusiasm amongst businesses it is strange to note that almost 30% of enterprises are still working on a mobile strategy and only 25% have had it for a year or so. What is hindering mobile adoption in businesses and specifically manufacturing? The remaining sections of this paper try and analyze the relevance of mobile applications for manufacturing and some of the challenged in adopting them. We also propose a step by step approach for holistic mobility strategy.

Mobility – Is it crucial for your enterprise?

Not all manufacturing organizations may see the same impact of mobility on their business. The application of mobility depends on the types of interactions as well as the type of manufacturing the business is engaged in. Manufacturing organizations experience three different types of collaboration:

The impact of mobility on a manufacturing organization also depends on the industry type:

1. Make to stock – These types of industries e.g. Consumer Durables are usually high volume products. The main applications of mobility in the core business are in sales and marketing, shop floor and supply chain. Consumer Goods companies for example, can use mobile applications to reach out to end customers, get feedback on products and understand consumer behavior. Mobile solutions also help in accurate pick and place operations.

2. Make to order – These industries e.g. Aerospace are low volume high value, customized products. For these industries mobility plays a major role in installation, configuration and field service and can help improve customer satisfaction through reduced downtimes during repair cycle. These industries also are leveraging mobility in the supply chain and shop floor area.

Creating a use case for mobility in manufacturing

Mobility finds its application across the manufacturing value chain of plan-source-make-sell. Some of the benefits of adopting mobile manufacturing practices are:

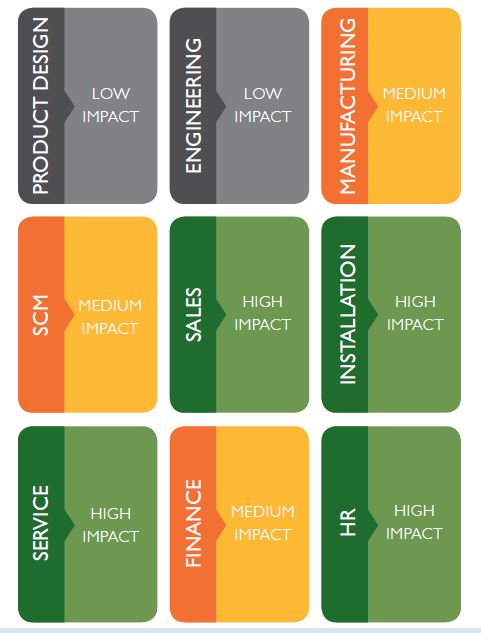

Figure 1: Impact of Mobility

There are nine primary areas impacted by mobility (see figure 1). It has a high impact on Sales & Marketing Services, Installation and HR processes as these either have a direct impact on revenue, customer satisfaction or employee productivity. For example, in servicing, the ability to access technical data as well as collaboration (such as remote video inspection) allows field technicians to fix field problems faster. In the highly customized segments (MTO, BTO, ETO) a field engineer can be greatly aided by these mobile enabled tools as he/she undertakes the repair process. In these cases product specific data can be available on the mobile device, the engineer can share defect photographs and specifications with an expert at another location and can resolve the issue faster without making multiple field visits. Mobile enabled HR processes can result in employee self-service scenarios that are highly cost and time efficient. Employees can plan travel, apply for leaves, fi ll time sheets, send updates on the move and get instant approvals.

In Supply Chain and Finance functions, mobility has a medium impact. In the area of SCM, typical impact areas are applications used to enhance visibility and aid real time decision making. Mobile applications can be ideally deployed for asset tracking and inventory management.

In Product Design, Engineering and Production, mobility still has a relatively low impact. However, Augmented Reality is a topic that is being explored to conceptualize design and monitor production.

While mobility is being used in functions like quality assurance, inventory management, stock in transit, factory applications etc. the impact is not visible to the outside world.

The Mobility Strategy

Unlike the traditional IT projects, the advent of mobile technologies has caught the IT departments in a Catch 22 situation. On one side, IT was unprepared for the extent and rapidness of impact while at the same time they were supposed to control and harness for maximum benefit to the business. This combination of factors has led to control moving from the IT department to business side of the organization. While traditional IT implementations required time to create business case and change management it was easy to implement mobility by buying a few devices and installing relevant apps. Hence, business functions have adopted various mobile apps depending on their specific needs without waiting for a go ahead from IT and aligning to the overall IT strategy. Today this situation has steamrolled in to a scenario where there is next to none standardization in organizations in terms of mobility adoption and the IT department is unable to anchor mobility centrally. Business specific mobility applications are running in silos creating challenges in maintenance, access and security. Companies are also losing out on leveraging their collective bargaining power where apps can be purchased for the entire organization instead of smaller business functions. Decentralization is also becoming a reason for slower adoption.

What we see clearly, is a lack of a top down mobility strategy leading to challenges in organization wide mobility deployment. There is a need to standardize methodologies , and mobility tools across the organization and build integrated solutions. Due to constraints of enterprise architecture mobility adoption is at best ad-hoc as of now. To reap the benefits of mobility, manufacturing organizations need a more coherent vision and centralized mobility architecture.

Companies need to make informed choices on mobile app deployment related to key dimensions of

At present the key challenges in a centralized mobility strategy are: a lack of clarity on ROI, identification of right tools and platforms, lack of technical and governance standards, inconsistent user experience and branding, end user engagement, security and scale of implementation.

Mobility needs multiple flavors of understanding including user experience and user design to be complete and comprehensive. Instead of a narrow focus on platforms, companies must look at a holistic picture - IT, tools & platforms, process transformation, user experience. User experience is the key component that differentiates a mobile implementation from a standard IT implementation.

To start on an integrated mobility journey an organization must look to establish a mobility center of excellence (CoE). This will be the central governing body for all enterprise mobility needs. The mobility CoE will define standard architectures, processes & guidelines to be followed, and analysis & decision processes for all mobile deployments. To create this CoE, organizations must evaluate the current IT landscape - baseline current mobility initiatives, identify usage patterns, demand sources, gaps and best practices. This needs to be followed by setting up a team with clear long term and short term goals. This team will work in close collaboration with the business to create guidelines, policies, engagement strategies and measurement frameworks.

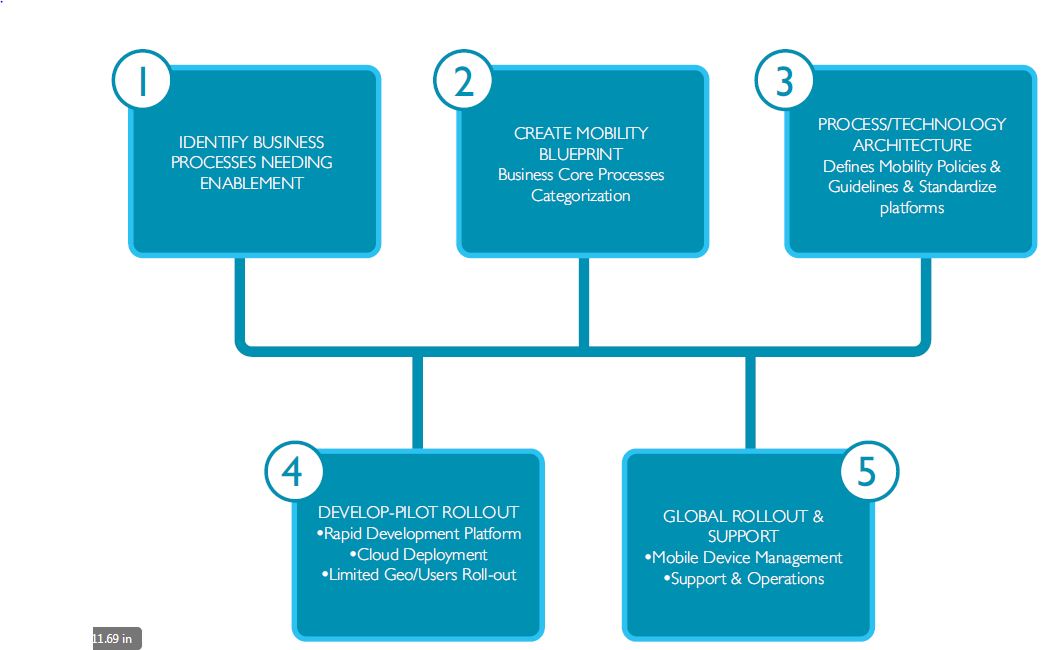

Once the mobility CoE is conceptualized, it can work on a 5 step model (see fi gure 2) that will help mobile enabled business transformation.

Mobility is not just UI/Apps, its about Business Process Transformation

Figure 2: Steps to a mobility-led business transformation

The Future is Mobile

The mobile revolution is set to transform the way business is done and that is true for all industries. It has hit the core of an organization i.e. its people – be it employees, customers or other stakeholders. The greatest acknowledged benefits of mobility are productivity, efficiency, collaboration, ease of information access and real time decision making. At the same time the biggest challenges this disruption is putting in front of businesses are data security and privacy concerns, information access controls, loss of centralized control.

For the manufacturing industry also, industry experts acknowledge that the benefits of mobility far outweigh the cost to overcome challenges. However, enterprises struggling to accelerate the mobility adoption in the system are in need of expert advice. Companies globally are partnering with leading mobility service providers to help them define, deploy and manage mobility CoEs that can deliver the benefits. A collaborative partnership approach, both internally within the business and externally with strategic consultants and vendors is the way forward for manufacturers to navigate this fast changing business landscape.

References

1 http://news.thomasnet.com/IMT/2012/07/24/manufacturing-goes-mobile/

Sudhakar Babu Tamminedi

Lead Consultant – Enterprise Mobility, Wipro Mobility Solutions

Sudhakar has over 15 years of experience in Consumer and Enterprise Mobility applications across industries. He has provided end to end mobility solutions from conceptualization to deployment. He has successfully led several large & complex mobility initiatives for key customers across different industries. He specializes in Mobile Strategy, Cross Platform Solutions, and Consumer & Enterprise Mobility

Venkata S Akella

Industry Principal – Manufacturing & Hi-Tech

Wipro Technologies, the global IT business of Wipro Limited (NYSE:WIT) is a leading Information Technology, Consulting and Outsourcing company, that delivers solutions to enable its clients do business better. Wipro Technologies delivers winning business outcomes through its deep industryexperience and a 360 degree view of “Business through Technology” – helping clients create successful and adaptive businesses. A company recognized globally for its comprehensive portfolio of services, a practitioner’s approach to delivering innovation and an organization wide commitment to sustainability, Wipro Technologies has 140,000 employees and clients across 54 countries. For more information, please visit www.wipro.com.