June | 2020

The COVID-19 crisis has affected demand, supply and workforce availability globally at the same time, a first-time occurrence in decades.According to a survey from the National Association of Manufacturers, more than 78.3% of manufacturers are anticipating a negative revenue impact this year.

The short-term impact on manufacturing has varied depending on the sector. Factories have either been shut down or are rapidly accelerating their production. The chemical industry has kept plants running to provide essentials like disinfectants and antiseptics. Industrial-goods companies are facing challenges like deferred demand, disruptions in supply, and potential closures, which are impacting retail and purchasing prices.

Manufacturers that have global, multi-tiered supply chains are facing disruptions also due to uneven recovery of regions across the globe. This has had a ripple effect across the supply chain. Supply of raw materials is disrupted. There is also a shift to smaller suppliers and local supply chains. Process Manufacturers are shifting to modular manufacturing, where they can produce items that are needed by the medical community and beyond. For instance, luxury brand LVMH has converted some of its perfume manufacturing facilities to produce hand sanitizer instead.

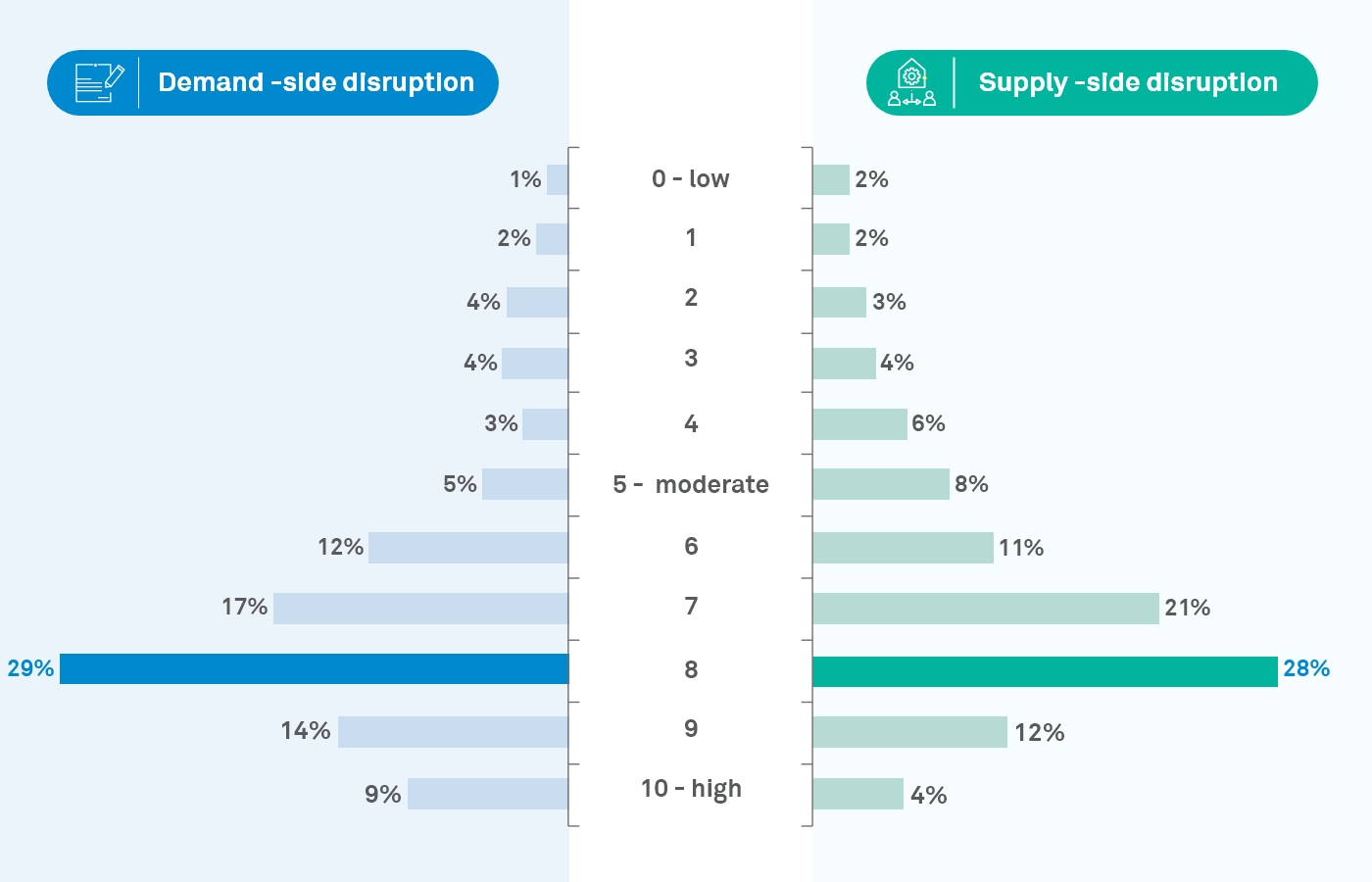

Figure 1: Source - How to rebound stronger from COVID-19: Resilience in manufacturing and supply systems, WEF

Where do we go from here?

The ongoing COVID-19 crisis has presented a double-edged sword for manufacturers – and the favorable aspect is an opportunity to transform business models led by digitalization and catapult business growth.

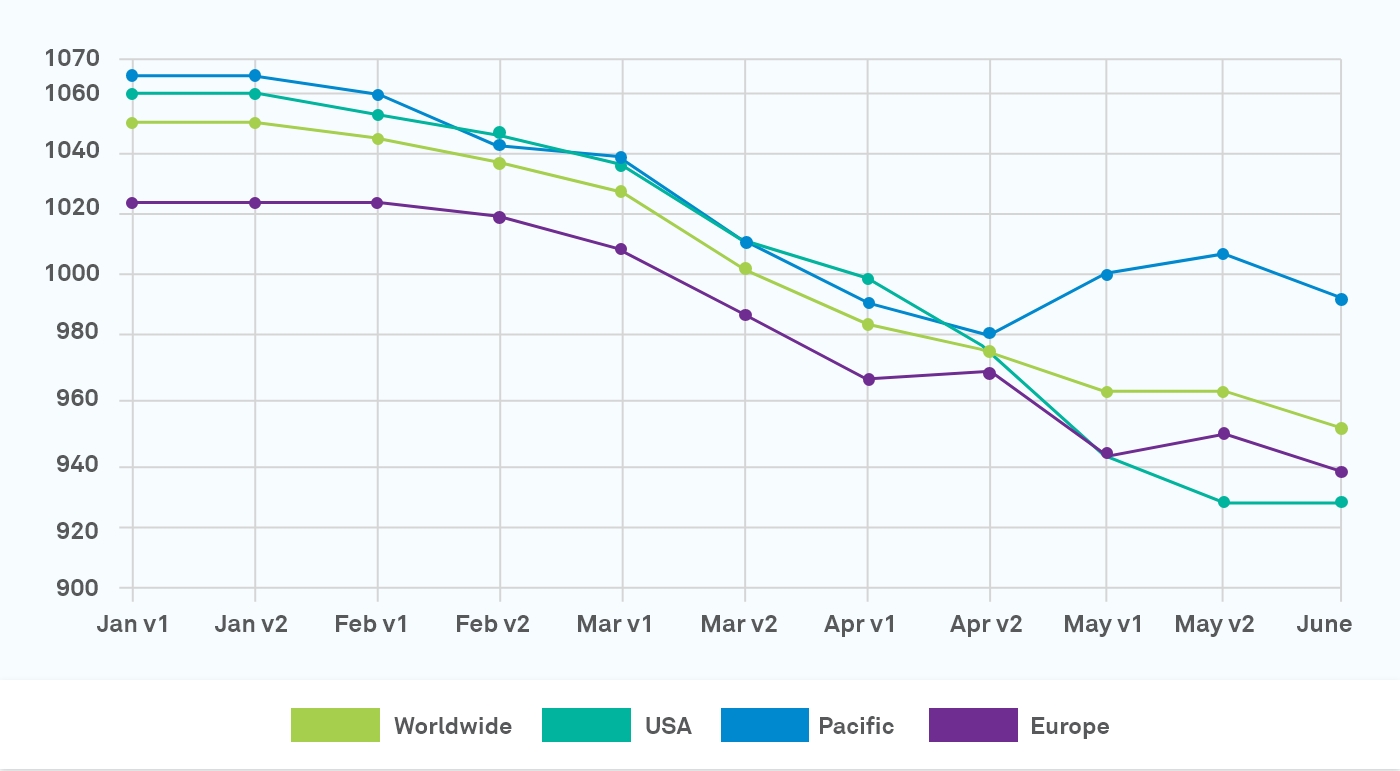

Our collective mindset is transforming – there is a renewed focus on health and safety, which will give rise to virtual collaborative frameworks, and flexible and agile businesses. Crowdsourcing will change our workforce: how we design, and how quickly we collaborate. And organizations that proactively realign their strategies and plans will be able to restart their business and emerge strong. Figure 2 showcases the technology index for various regions during COVID-19 up until now.Asia pacific is positive, Europe has stabilized, and experts are expecting US to follow suit.

Figure 2: Source – IDC COVID-19 Tech Index, June 2020

This COVID-19 crisis-driven downtime has given manufacturers the opportunity to rethink strategic priorities. While organizations look at ramping up, it is critical to prepare for future capabilities that can transform business models. The reality is – more essential now than ever – manufacturers must digitalize their processes. And the need for a right technology partner and a partner ecosystem that can enable organizations to assess, prioritize and act is acute.

Short-term technology investments will be around the following areas:

Digital: An enabler in the new order

Although manufacturers have embarked on their digital journeys, and each is at different stages of adoption, in order to realize the full potential and benefits, effective usage of digital tools and technologies is imperative. The manufacturing industry will eventually recover from the crisis, but what would matter is the speed at which these digital technologies can be essentially integrated in order to yield the highest level of productivity and prepare for a transformative future.

The near future will see organizations shift their ways of working and focus areas/priorities:

The 3-prong approach to digital transformation

A 3-step approach will help prepare for the future of business and transformation

Assess – There are a number of digital technologies, each designed and developed to achieve a specific function and purpose. Adopting the right technologies can help organizations to enable its employees to deliver safely and seamlessly on the processes and outcomes.

The ongoing situation has forced many manufacturers to pull up their plans of implementing remote monitoring and diagnostics of operations and assets earlier than originally planned. Connected assets and IT-OT convergence can aid organizations to restore operations and run critical-to-business activities without jeopardizing the safety of its employees.

10 major potential digital manufacturing opportunities

Prioritize–With strong foundational technologies in place, the PMO should dedicate ‘preparation’ of people, process and platforms to scale new business requirements. Enabling remote working of people and cost optimization are the biggest priorities for manufacturers right now.

Knowing what technologies to invest in is not enough when businesses accelerate their investments to bounce back to business growth. Here is where, having a framework truly helps. This will enable organizations to prioritize the top actions around remote work, building a business resilience matrix, cost optimization measures focused on digital solutions across key business and IT realms.

An instance is Wipro’s $AVE framework for manufacturers:

Frameworks help organizations identify value streams, discover areas of the business where cost is inflated and develop a prioritization funnel of solutions based on your business needs.

Act – We observe that organizations are building a phased plan of action. Some investments are already completed and underway for immediate short term benefits that have helped organizations with business continuity. And some have clearly accelerated their plan to action and will move into the implementation phase soon.

Here is what we see happening in the industry:

Short Term Investments

Medium Term Investments

Long Term Investments

Towards resilience

Organizations have moved past viewing this crisis as a hurdle to their business growth and have started planning to accelerate their journey to digital primacy. With a technology partner, this journey becomes easier and faster. The crisis has certainly provided an opportunity, and the time to reimagine your business is now.

Ashish Saxena

Vice President and Business Head, Manufacturing - North America, Wipro

Ashish has 25+ years of experience leading many Fortune 500 and Global 1000 client relationships across Asia, Europe, and North America.