November | 2019

Sand production is a worldwide phenomenon, a process that inhibits the production volumes and rates of wells across the globe and has significant limiting impact on the field development planning exercise. Millions of dollars are spent on an annual basis in order to mitigate the issues related to sand production, thereby creating huge economic loss for the operators. The first step in order to recognize and mitigate this issue is the development of an accurate sand prediction model which defines the extent of sand production throughout the life cycle of the well or the field. Once this is defined with a reasonable extent of certainty, the operator has to decide whether it can operate economically and safely with the expected sand production rates (if any) or it has to implement sand control techniques in order to meet the desired rates of production and the associated drawdowns. Moreover, in the current scenario of uncertain oil prices, the cost of making an error with respect to standalone prediction models may be humongous. This facilitates the need to supplement these models with recent advancement in analytics techniques to minimize the scope of error.

Changing sand prediction/management philosophy

In the current oil price environment, all new developments are pursued with minimum capital investment and lowest possible operating cost to improve project economics. Projects that do not meet the economic criteria have to be shelved or deferred to a later date. One possible area for cost reduction is sand management. The idea is to defer the installation of expensive sand control techniques and come up with a fit to purpose sand management strategy. The existing sand prediction model can be retrofitted with the analytical model and existing sand production data of the field to assess the potential of future sand production and a best practice sand management strategy.

The analytical model backed by geomechanics will enable to augment the sand prediction model, which in turn will enable the operator to select the type of sand control measures and sand management techniques. The model needs as input data, the reservoir characteristics and a geomechanical model derived from well logs that includes the stress state regime. It also requires the well direction, azimuth and completion information in order to evaluate the well characteristics.

Predicted sand production in most new wells is manageable. Some wells targeting shallower or weaker sands would normally be sand control candidates, but re-thinking the completion design, optimizing surface sand management procedures, managing drawdown and BHFP levels, and taking advantage of favorable stress vectors through oriented perforation along with the use of advanced analytics can extend the sand free well operating envelopes over life of well production and depletion conditions, reducing or deferring the need for sand control in all but the highest sanding risk reservoirs.

Why Operators should think about it?

The anchor points that operators should consider:

Fit-to-purpose sand management strategy: Instead of relying on a single sand prediction model for the entire life cycle of the field, the use of analytics provides a fit-to-purpose sand management strategy at different stages of the field development cycle. The use of predictive analytics on a regular basis along with the model updation with the latest sand production data not only helps the operator to fine-tune the current sand management strategy but also decreases the likelihood of unplanned deferment due to sand issues.

Substantial future benefits at marginal cost: An ineffective sand management strategy can lead to erosion issues and lost production due to the need for regular separator clean-outs, and is a key risk factor for both existing well integrity and new well completion design. This degree of risk can be minimized if not eliminated by augmenting the engineering judgement with predictive analytics techniques. Moreover, the cost of this preventive technique remarkably undershoots the cost related to the corrective measures and techniques implied due to sand issues and a subsequent production loss.

The legacy data advantage: Predictive analytics works best when there is an abundance of historical data in order to make predictions about the future using statistical techniques and machine learning. With fields having years of legacy data related to rates and sand production, the analytical approach will provide substantial benefits in terms of an effective sand prediction and management strategy, thereby enabling the extension of sand free well operating envelopes. In addition, the complexity and uncertainty of the production and geomechanical dataset can be taken care of by predictive modeling and analytics, given the minimal run-time of the model as compared to a full-fledged standalone sand prediction model.

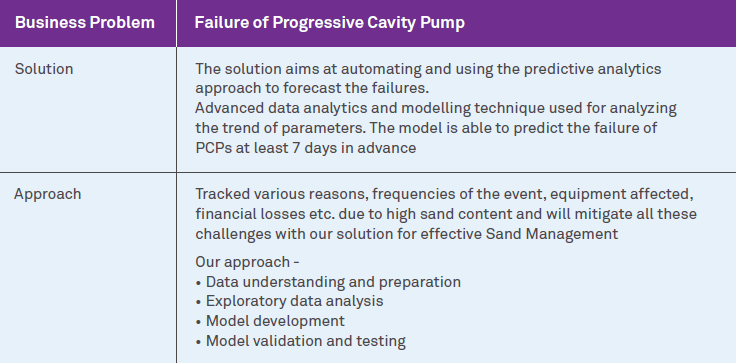

Use cases

Aviram

Principal Consultant

Aviram is a Principal Consultant with the Drilling and Production consulting practice, specializing in the areas of upstream Production Operations, Process Excellence, Digital Oil Field and project and stakeholder management. He has 10 years of experience in the Oil and gas industry with a background in Petroleum engineering and Data Science. Started his professional career as a Production engineer and subsequently associated with major Oil & Gas companies as a Production Engineer, Sr. Advisor, Consultant, Business Analyst, and Digital Transformation Leader.

Aviram can be reached at kumar.69@wipro.com.