The aviation sector is responsible for 2% of global CO2 emissions. Among the set of measures to reduce emissions — such as new aircraft technologies and operational efficiencies — Sustainable Aviation Fuel (SAF) could be the most impactful intervention. Blending SAF into traditional jet fuel (and eventually replacing traditional jet fuel entirely) could contribute up to 65% of the emission reductions required for air travel to reach net zero. As such, SAF could be the single most important initiative related to aviation decarbonization.

The increasing demand for SAF is being driven by both regulatory mandates and voluntary initiatives. Products that include SAF are becoming more commercially attractive to energy companies that supply jet fuel, and technological advances related to both raw materials and production efficiencies are making SAF incrementally more viable. RefuelEU, the relevant mandate covering EU countries, has set a target for SAF to make up 2% of aviation fuel consumption in 2025, with the SAF rate rising to 70% by 2050. Such mandates, along with voluntary purchases (fixed volume, percentage, or bulk) are challenging fuel suppliers to incorporate SAF into their mainstream jet fuel supply chains.

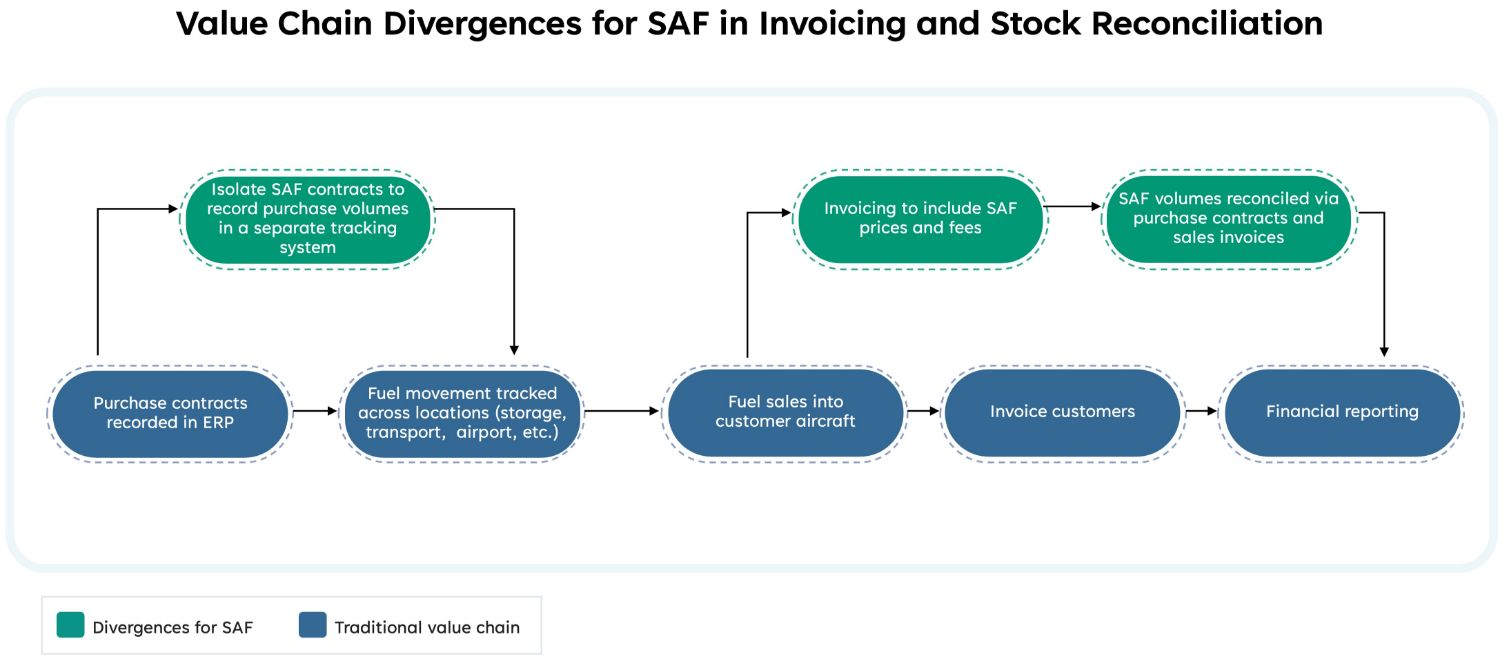

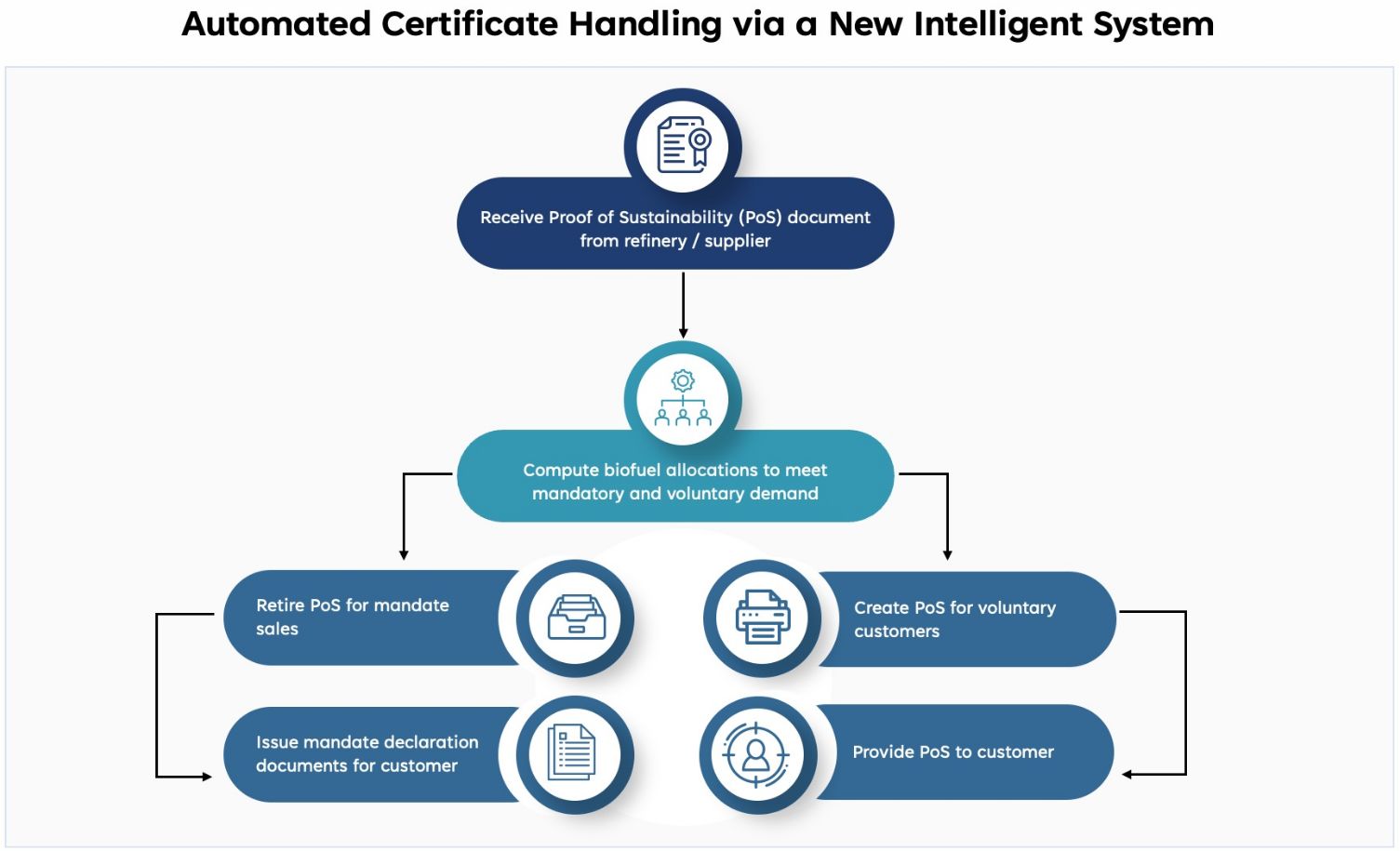

However, bringing SAF products to market is more complicated than it might at first seem. Blending SAF into jet fuel products requires changes in business processes, physical infrastructure, and IT systems to both support physical delivery and maintain full traceability of SAF molecules in the fuel value chain for regulatory compliance purposes. A fully integrated supply chain for both SAF and jet fuel will need to support both “segregated” and “commingled” delivery methods, enable “book and claim” transactions, and precisely track SAF concentrations and production methods from initial production all the way to consumption.

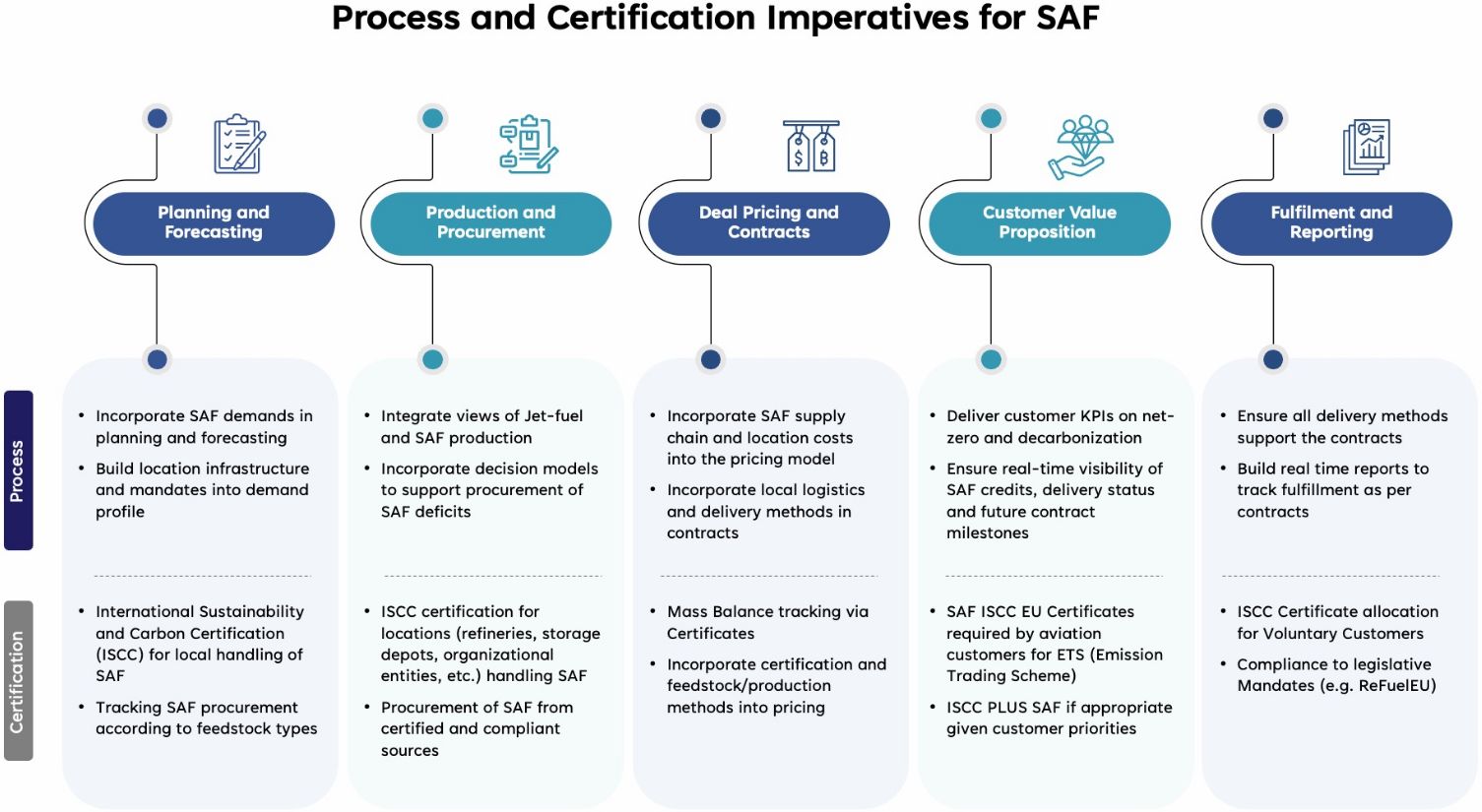

To address these challenges, Wipro has been working with market leaders in the jet fuel sector to build new capabilities for SAF enablement. Based on these experiences and engagements, we are increasingly focused on a specific set of process and certification imperatives (see Figure 1).