January | 2021

Structured asset performance has been mitigating equipment risk and driving long-term solutions in the oil and gas industries since at least the last decade. Recent advances in technology in the field of Asset Performance Management (APM) has further ameliorated the process by providing actionable recommendations in lieu of static notifications. However, this paper goes a step further and discusses ideas to propel business forward with collaboration between asset performance information and the market. It is less about warnings anticipating equipment failures and more about identifying opportunities to mitigate the negative impacts of such failure events.

Oil and gas operations require a diverse set of complex assets. In many cases, these operations are in remote and hard-to-access locations where monitoring equipment health and performance presents a substantial challenge. Whether the asset is an offshore pumping station, compressor, drilling rig, transportation equipment, pipeline booster station, or any other critical piece of equipment, throughout the upstream, midstream, and downstream processes, real-time health and performance insights can be used to influence decisions and actions that will drive efficiency and improve competitive advantage. This asset health data is already being created and can be used in maintenance and asset management programs to mitigate risk and ensure that critical equipment is operating as expected.

Broad industry research indicates that most plants’ operations still resort to reactive and break-fix maintenance, which involves letting an asset run until failure due to either age or wear-and-tear of the asset. This approach is possible only in case of non-critical assets that have little or no immediate impact on safety and have minimal repair or replacement costs such that they do not warrant an investment in advanced technology for failure prediction. The same research indicates that proactive strategies are rare in practice. Such non-proactive approaches to managing production assets puts businesses at significantly higher risk, both physically and financially. Thus the need for a better, collaborative approach.

Gradually, the Oil and Gas Industry has moved toward a Preventive Maintenance (PM) approach–implemented with the hope that an asset will not reach the point of failure if operators continuously monitor and maintain the asset. A preventive maintenance strategy prescribes maintenance work be conducted on a fixed schedule, or based on operational statistics, or manufacturer and industry recommended best-practice policy, or regulatory requirements. This is still an expensive process as assets may operate longer – resulting in delaying expensive Original Equipment Manufacturer (OEM) driven periodic maintenance.

For more complex and critical assets, a Predictive Maintenance (PdM) approach is being explored by the industry. PdM relies on generating metrics based on continuously monitoring asset performance data collected by sensors and passing those metrics to prediction engines whose purpose is to provide early and precise warning of equipment problems and the subsequent prevention or elimination of unplanned failures. PdM typically uses Advanced Pattern Recognition (APR) and requires a predictive analytics solution for real-time insights of equipment health. As a part of predictive maintenance, it is pivotal to leverage the maintenance processes described below before exploring prescriptive maintenance strategies to ensure the availability / presence of sufficient and reliable data which can be used for sophisticated solutions.

Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is a customized maintenance process determined through the analysis of potential failure modes and their impact on system performance. RCM preserves system functionality by identifying the potential failure modes before exploring and weighing the causes and consequences in depth. This eases the prioritization and categorization of failures and assignment of maintenance tasks.

RCM defines any unsatisfactory condition – from a slight degradation in performance, to total loss of function – as failure. RCM ensures that cost-benefit strategies are not used to reduce discretionary maintenance expenses until safety and security aspects are met. Factors such as age and usage are evaluated against maintenance costs to avoid assigning costly protocols to low-value assets. It collates feedback provided through maintenance history and uses it, not only to improve the design, but to also predict asset lifecycles and extend equipment life, and make replacement decisions based on equipment condition rather than a predetermined lifecycle.

RCM can eliminate the guesswork in selecting among predictive, preventive, or run-to-failure strategies and lead to improved overall cost performance, reduced downtime, and greater insight into the overall risk profile of the organization. As more failures are prevented, operational expenditures will benefit from reduced repairs, overhauls, and downtime.

It cannot be denied that RCM is one of the most efficient overall maintenance strategies because more complex maintenance processes are only applied when a strategic cost benefit has been established, and lower-value maintenance activities can be identified and eliminated in favor of appropriately scaled run-to-failure or more limited scheduled maintenance approaches.

Risk-Based Maintenance (RBM)

Risk-Based Maintenance (RBM) uses a risk assessment methodology to assign scarce maintenance resources to those assets that carry the most risk in the event of a failure.

risk = likelihood x consequence

Equipment that has a higher risk would be subjected to more frequent maintenance and inspection, resulting in reduction of the total risk of failure across your plant in the most economical way. RBM is essentially a preventive maintenance strategy in which the frequency and scope of maintenance activities are continuously optimized based on the findings from testing or inspection and a thorough risk assessment.

Condition-Based Maintenance (CBM)

Condition-Based Maintenance as a strategy looks for physical evidence that equipment failure is occurring or is about to occur, as many failure modes do give some warning other than the age of the equipment. If failure can be detected in the early stages, it may be possible to take action to prevent it from failing completely and/or to avoid the consequences of failure.

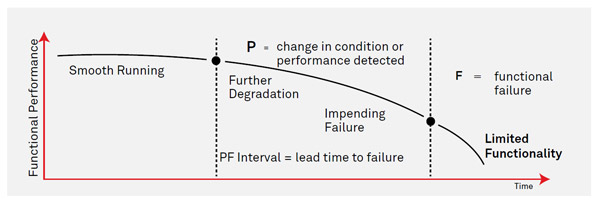

Meanwhile, CBM shows its broader application outside condition monitoring techniques, which are often only associated with rotating equipment. You can look at the P-F curve shown in the figure below to understand this.

P – Change in condition or Performance detected

F – Functional Failure

The curve shows that as a failure starts manifesting, the equipment deteriorates to the point at which it can possibly be detected (point “P”). If the failure is not detected and mitigated, it continues until a functional failure occurs (point “F”). The time range between P and F, commonly called the P-F interval, is the window of opportunity during which an inspection can possibly detect the imminent failure and give a time & opportunity for maintenance personnel to address it.

A common rule of thumb is that the interval between CBM tasks should be one-half or one-third of the P-F interval. Effectiveness of CBM depends on how long the P-F interval is. Failure modes where the P-F interval shows a large variability, condition monitoring is not an effective strategy. With plenty of warning, the rectification can be planned, materials and resources can be mobilized, and breakdown prevented (though production is still stopped for the maintenance duration). When the P-F interval is only a few days, the resulting organizational and workplace actions are much like a breakdown and the value of CBM is largely lost.

It is important to realize that CBM as a maintenance strategy does not reduce the likelihood of a failure occurring through life-renewal, but instead is aimed at intervening before the failure occurs, on the premise that this is more economical and should have less of an impact on availability. An efficient and effective process for data gathering, data analysis, decision making, and finally, early intervention, is critical for the success of CBM.

Most organizations have either adopted or evaluated one or more of the techniques discussed above to predict or prevent failures. While such techniques enhance asset performance, we believe it is critical to prescribe a relationship between the operation window and the failure type using analytics and data science, and find a more robust approach in order to understand the reasons behind the problems leading to the failures.

Every equipment has an operating range to cope with alterations/variations in operating conditions like flow, pressure, temperature etc. Overlaying, the thermodynamic equation of the equipment over the failure prediction generated from above techniques, based on the level of operation; operators can try to define the particular operating level and set certain target points. Since we know every equipment has an operating range to cope with alterations/variations in operating conditions like flow, pressure, temperature etc. and by calculating the thermodynamic equation, we can decide the prediction failure type based on the level of operation. Operators can then try to define the particular operating level for particular predictive fail, set to certain target points. The goal is to play with the operating window to maintain the demand either (surge or reduce) based on insights collected from collaboration with multiple sources.

When a change in the data related to any equipment/asset occurs, Prescriptive Maintenance (PM) will let us evaluate when and where failure is going to happen but also why it is happening. The reason behind the failure helps the PM identify different options and the potential outcomes to mitigate any risk to the operation along with the probability of success. With this information, the PM can prescribe the operating level to manage the lifespan of the equipment. This is a paradigm shift from current industry initiatives around Asset Performance Management and only a handful of organizations have already started experimenting with the technique for their critical equipment.

Conclusion

We have observed that APM can be leveraged beyond managing the Safety monitoring and Maintenance purpose for asset-intensive organizations but it can also generate information that propels business decisions. Every decision taken by the Asset Performance team impacts - supply, operations, blending, and almost all other business functions, and eventually translates to the end customer whose demands drive the market. Leveraging asset efficiency and failure information to adjust supply positions puts them in a market advantage. Thus, we believe the industry should move toward the new paradigm with the combined power of business collaboration to prescribe the relationship between the failure time and operating range to get the highest value. Asset Performance today should be more than just a technology play to predict or prevent the failure of a set of equipment. To realize differentiated value in this highly competitive environment, we need to consider moving toward a unified strategy that connects multiple people, functional processes, and technology to work together. We are seeing the industry trying to drive transformational value leveraging asset performance when they can transform / rely using simplified, collaborative processes built to leverage the power of industrial internet. Let us consider an example of a pump that is continuously monitored. There is a small change in the operating metrics of the pump. The PM detects it and provides an option to repair the piece of equipment with an estimated success outcome of 80%, while an upgraded replacement of the equipment will give a successful outcome of 95%. Now, the maintenance staff can weigh the cost and success outcomes to make the most cost-effective decision. Predicting alone doesn’t seem sufficient if we are not aligned with the market demand and shipment plans. With increased digitization of the assets, it would be eventful if we could merge these actionable recommendations with the market by connecting data and trigger points across the system. The asset performance, maintenance improvements, market demands can all be connected to improve the core operation resulting in significant financial results.

Rekha Paudel

Consultant, Downstream oil and gas, ENR Consulting

Rekha Paudel is a Consultant in Wipro downstream oil and gas and a chemical engineer by profession. She has over 5 years of industry experience in the oil and gas industry, mainly in the areas of Planning, APM, Crude Assay Management, Energy Management, and Refinery technical services. Before joining Wipro, she was a Senior Analyst for Accenture and worked in Green field implementation projects. She can be reached at rekha.paudel@wipro.com