Solving Five HSSE Puzzles in the Mining Industry

This white paper offers solutions to significant health, safety, security and environment (HSSE) puzzles faced by mining executives around the world in five areas: Energy management, remote operations, operational safety, skill/knowledge retention, and environmental/social compliance.

Many HSSE puzzles in the mining industry can be solved through effective application of technology. All five of the puzzles discussed here are examples where proven technologies can improve performance and minimize risk. A mining enterprise should engage a technology partner with the right expertise to support the right HSSE solutions from design to full deployment. Such a partner will be well-versed in the best-fit-for-need applications and tools (and the vendors that offer them) as well as in project and change management. This will ensure that an HSSE solution fits the puzzle and produces the desired results.

Health, safety, security and environment (HSSE) issues are central to any mining operation. The industry has made great strides in its adoption of technologies that allow improvements in many aspects of HSSE. However, there are still puzzles that mining companies must solve in order to improve the ability to protect personnel, sustain operations, and safeguard the environment.

This white paper is an overview of five significant HSSE puzzles faced by mining executives around the world, along with the recommended technology-based approaches for their solution.

These five puzzles reside in:

Wipro Technologies specializes in the practical application of technology to solve puzzles like these. For more than five decades Wipro has addressed similar issues in industries that have some of the same characteristics as the mining industry. We have “translated” proven solutions from a number of industries into mining-specific strategies.

Puzzle #1 – Energy Management

“The world economy needs ever-increasing amounts of energy to sustain economic growth, raise living standards, and reduce poverty. But today’s trends in energy use are not sustainable. As the world’s population grows and economies become more industrialized, nonrenewable energy sources will become scarcer and more costly.”

- World Bank

Mining operations are significant energy consumers. Regardless of the material being mined or the type of operation, every phase of work requires energy in some form. As a whole, the industry has come under the scrutiny of government agencies because of its share in energy use. For example:

According to a report published by the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy, U.S. mines spend approximately 17 percent of the total cost of supplies on energy. 2 These percentages can be considered valid approximations (and likely at the low end) of energy usage for mining operations in other parts of the world.

Around one-third of this energy requirement, for use in crushing & grinding, dewatering and ventilation systems, is supplied by electricity. Another one-third, for transportation and hauling, is supplied by fuel oil. The remainder is supplied by natural gas and coal.

The need for cost-effective energy presents an ongoing puzzle to mining enterprises. As nonrenewable energy sources become scarcer and as mining companies move into increasingly remote locations, management must find innovative ways to supply sufficient energy of the right type to allow uninterrupted operation.

Solving the Puzzle

This puzzle can be addressed through an increase in energy efficiency and through use of renewable energy wherever possible. As examples:

These instances combine renewable energy with energy efficiency. Both of these examples demonstrate the need to fit solution to location:

In other words, an energy management solution is likely to be specific to a particular location and will certainly be impacted by economic and governmental conditions. It is important, therefore, for a mining enterprise to take on the right technology partner when pursuing innovation in energy management.

Wipro EcoEnergy specializes in sustainable and energy efficient industrial-scale solutions based on proven and commercially viable technologies. These solutions, combined with our knowledge of the mining sector and expertise in program implementation, provide the innovation needed to create renewable energy sources at mine sites and to ensure energy efficiency in work processes.

Puzzle #2 – Remote Operations

From both a business and safety standpoint, mining enterprises are arriving at a key conclusion: The fewer feet on the ground the better.

The mining industry often plays the role of “pioneer,” entering and setting up operations in remote locations. The range of HSSE-related risks is broad, encompassing that movement of personnel to and from the mine site, assurance of worker safety on the surface or underground, and accessibility to critical expertise to support effective decision making. Enterprises are seeking ways to keep the number of people actively working a site to an efficient minimum while putting the right skills at the right place at the right time.

This last point can be a significant challenge. Skills needed in mining projects generally fall into three categories:

As might be expected, the third category of workers is in extremely high demand, both between companies and within an enterprise. These individuals can easily become “spread thin” as they spend time traveling from site to site.

Solving the Puzzle

With the number of young qualified workers on the decline, it is important to make most effective use of human assets. Technology can offer some of the best solutions to this puzzle. For example:

The Wipro Collaborative Decision Environment (CDE) minimizes issues related to geographic separation and makes specialized knowledge and expertise more readily available without physical travel. By providing the right information to at the right time to the right people regardless of their physical location, the CDE leverages high demand skills and facilitates better and more efficient decision making.

Puzzle #3 – Operational Safety

Mining crises have occurred to greater or lesser extents in locations around the world in recent years. Among the most serious ones were:

Operational safety is comprised of a number of management puzzles. Proper processes and methods must be applied throughout a mining site and its lifecycle, from construction of supports to correct operation of large equipment. At an enterprise level, operational safety is bracketed by four strategic factors (increased regulatory focus, workforce demographics, organizational culture, and operating pressures), and management across the mining industry must answer key questions in relation to safety programs:

We have identified three major challenges that impact the effectiveness of operational safety procedures and systems:

In a company with enterprise challenges related to mine safety, onsite operations require:

When an emergency occurs, the communication system must provide a comprehensive, real time view of the situation in order to maximize human survival, preserve equipment, and keep financial impacts to a minimum. The system must also be able to:

Worker fatigue presents further challenges to operational safety. Weather conditions, jobs with lots of repetitive tasks, and changes in shift pattern are examples of factors that can increase worker fatigue, which in turn can increase operational errors because personnel are less alert and more prone to faulty decision making.

Solving the Puzzle

Operational safety engagements conducted across several industries have allowed us to identify four key leading practice areas that can greatly improve operation safety procedures, monitoring, and risk management across an enterprise. The end result of these practices is an operational safety program that consists of:

These areas are best pursued sequentially, meaning that putting them into play is a stepwise progression from the first to the fourth.

The need to communicate with and monitor the location of mine workers has been recognized by mining organizations as well as government regulators. This need covers prevention (monitoring workers and equipment on an ongoing basis in real time) as well as emergency response. For example, legislation such as the U.S. MINER Act of 2006 mandated development of emergency communications and tracking mechanisms.

Communication and monitoring systems must suit the type of mine; for example, a system at an underground mine must work both above and below the surface while maintaining mobility. The range of equipment and networking options must be considered and a best-fit solution for mine configuration and personnel activities must be identified. This requires multidisciplinary planning and implementation.

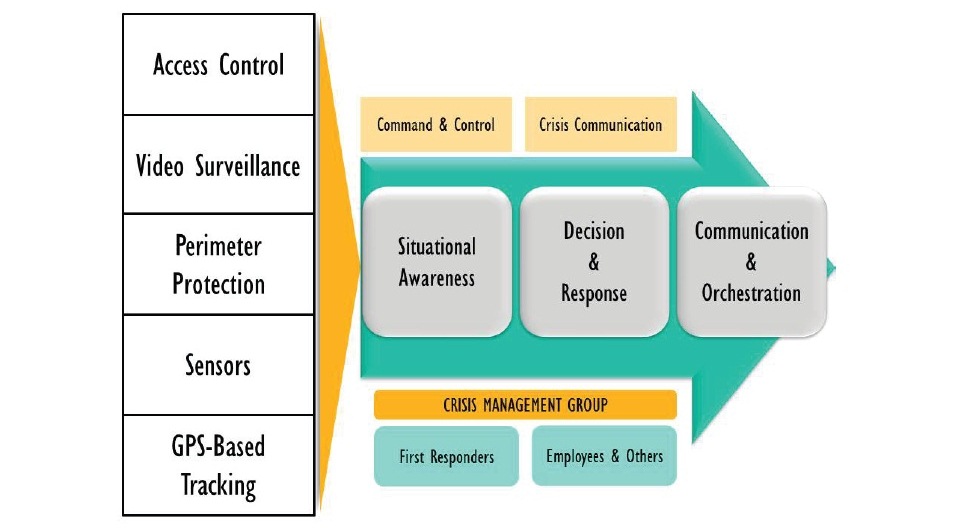

The full solution to the operational safety puzzle relies on the effective onsite combination of people, process, and technology as well as seamless integration of multiple systems from different vendors. Figure 1 illustrates the functionality of an effective safety communication/ monitoring solution.

Managing fatigue-related operational risk can be greatly enhanced through technological tools. For example, risk assessment software can be implemented to help management determine the state of mine workers so that fatigue-related safety hazards can be eliminated. Worker alertness can also be measured and monitored using automated systems such as Infield Task Observation and biometric measurement.

Wipro Technologies brings people-process-technology cohesion to the solution of the operational safety puzzle. Based on our knowledge of mining operations as well as relevant experience in other industries (notably manufacturing and oil & gas), we incorporate the appropriate current technologies into existing systems and processes both onsite and in central monitoring locations.

Figure 1. Components and Functions of an Effective

Puzzle #4 – Skills Shortage/ Knowledge Retention

The shortage of skills in the mining industry is a welldocumented puzzle, and one that plays in to HSSE concerns. As mining operations move increasingly into emerging markets, access to skills comes into question. Further, the trend toward increased capital project investment—in 2010 the top 40 firms announced plans totaling of $300 billion in capex investment—puts additional pressure on the talent pool.

There is also the issue of replacing current workers as they age and retire. The number of workers entering the industry is insufficient to keep the total workforce numbers the same. Even if a “one for one” skill replacement took place, experience gained from years in the field can disappear along with the insights and practices that keep a site safe and in compliance with rules and regulations. Lack of right skills in the right place increases risks in decision making and site activities. Mining enterprises must deploy current skills inventories to minimize these risks and to retain the skills and expertise of the workforce.

Two factors that can be addressed through technologyenabled solutions are:

Organizational knowledge retention. The mining industry is characterized by large and complex operations and many these operations have moved into new locations or are digging deeper for lower grade materials. Enterprises, however, have not adopted methods to capture and retain the knowledge gained on mining sites and to make that knowledge easily accessible to personnel. This has led to “corporate amnesia” that has been at least partly responsible for mine accidents.

Competency-based risk. A single decision based on insufficient experience can put mining personnel and operations at serious risk. It can also damage even the most well-established business. With today’s workforce comprised of a combination of employees and contractors, it can be difficult to confirm that the competency level of each worker is appropriate to their role. Without a strategy for determining who will work in the mine (and in what capacity) that ensures that the right capabilities are being deployed, staffing decisions may be less certain and put mining activities at risk.

Solving the Puzzle

Crisis prevention/management can be supported by a number of technology-based solutions. In terms of the two factors presented here, technology can be implemented for:

1.Capture and re-use of organizational learning and knowledge. In addition to providing ready access to formal documentation through webor cloud-based sources, organizations can implement processes that capture learnings and insights directly from onsite personnel and then “package” this knowledge into forms that can be easily found and used by operational site throughout the enterprise. Further, these processes will retain learnings, which will help dispel the corporate amnesia that can impair safety.

2.Competency-based risk management. Competencybased risk must be minimized by:

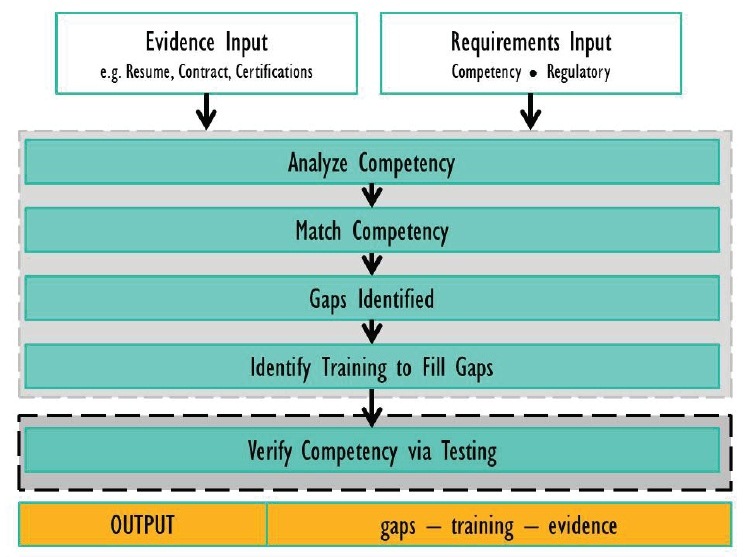

Further, accredited training and certification are essential to reduce competency-based risk. Because conditions at a job site can change, skills verification must be made on a periodic basis for both employees and contractors. Figure 2 offers an example flow for a competency-based risk management process.

Wipro knowledge management consultants have experience in all forms of knowledge capture and reuse. Formal documentation as well as knowledge “nuggets” from key experts can be made accessible across an organization via web- or cloud-based infrastructure. In addition, Wipro’s Competency Risk Management solution automates the screening and testing of employees and contractors for competencies that are critical for safe operations. The system ensures that roles are being performed by qualified individuals and that skills are refreshed on a regular basis.

Figure 2. Example Competency-Based Risk Management

Puzzle #5 – Environmental/ Social Compliance

Protection of natural resources and the environment is a key objective of regulatory bodies in every region of the world. Though not a new item on the governmental agenda, environmental compliance by mining operations has continued to increase in stringency and now encompasses all aspects of impact to land usage, water balance, air and noise pollution, flora and fauna and nearby communities. This increase has been brought about by changes in the industry:

Changes like these are prompting regulatory agencies to increase information and reporting requirements.

Social compliance is also an important environmental factor. Local stakeholders constitute a powerful force that can support or destroy the success of a mining venture.

Mining companies that are also mine operators, compared to companies that find, prove, and then sell properties, want to purchase properties that have proven deposits and that are economically feasible from a business standpoint. They want to get into production as fast as possible in order to minimize financing costs. Any factors that could slow down the process to production will adversely impact the economic viability of the operation. Therefore, even though a property might have a proven and viable deposit, the presence of socio-political obstacles or risks can bring a planned operation to a halt. In other words, the property must appear to have social compliance.

With respect to social license, the “find and sell” and “find and operate” companies have different strategies. The former strategy does not call for social license investments, while the “find and operate” strategy of operating mining companies must include social license issues in their property analysis, and must justify pursuing properties that have ignored these issues. Supply and demand has an impact on this justification: When mineral prices are high and properties are scarce, buyers are more willing to accept the cost of dealing with stakeholder relations challenges. When mineral prices are low and/or properties are plentiful, buyers/operators can be more selective.

Solving the Puzzle

Environmental and social compliance call for incorporation of sustainability practices as core business strategy (as opposed to a siloed business approach, which was the norm for decades). Sustainability must be a key focus throughout a site’s life cycle, from analysis of feasibility of deposits to mine reclamation.

In today’s marketplace, sustainable businesses (i.e., those have no negative impacts on the environment, community, or economy in the areas in which they operate) gain additional shareholder and competitive value because of their practices. Strategic investments in sustainability can be strong drivers of growth and profitability if executed effectively. Though “compliance” might be the initial objective for implementation of sustainability practices, results extend beyond regulatory requirements. Technology can help identify issues beyond the regulatory framework; for example, monitoring of social networking sites can pinpoint issues or activities that could adversely impact a project so that proactive measures can be put into place to prevent crises.

Business sustainability as an HSSE puzzle solution combines people, processes, and technology to meet strategic objectives and mitigate risks. Proceeding in a stepwise manner, specific drivers are identified for a given operation or site. Objectives and targets that address environmental and social issues are created and the actions for their achievement are identified. These actions are incorporated into projects which are implemented and monitored. Automation plays an important role in these projects, both in terms of data capture and results monitoring.

Wipro’s Business Sustainability Framework is a step-bystep methodology that helps mining enterprises create and execute a successful sustainability strategy. Along with a global ecosystem of provider partners, we help clients manage auditable environmental and energy inventories and make cost-effective operational improvements that improve social license. The framework follows regulatory requirements and voluntary guidelines embodied in instruments including but not limited to the Kyoto Protocol, EU ETS, UK CRC, and US Clean Air Act.

Conclusion

As global resources diminish, organizations need to innovate to sustain themselves. Many HSSE puzzles in the mining industry arise from resource constraints, and effective use of technology can be the basis for successful solution. All five of the puzzles discussed here are examples where proven technologies can free up critical resources, improve performance, and minimize risk.

Technology alone, however, does not provide the full solution. Technology projects must be designed and implemented effectively. In addition, a technology solution may need to be customized on a site-by-site basis in order to take a variety of factors such as mining type and governmental regulations into account.

Human behavior must also be considered when putting HSSE puzzle solutions into place. It is important to manage change effectively to ensure that new processes and workflows are fully adopted by mining personnel. Finally, in cases where a solution requires the integration of multiple technologies from a number of vendors, the design, implementation, and change management can present puzzles of their own.

With these considerations in mind, a mining enterprise should engage a technology partner with the right expertise to support the right puzzle solutions from design to full deployment. Such a partner will be well-versed in the right applications and tools (and the vendors that offer them) as well as in project and change management. This will ensure that the HSSE solution fits the puzzle and produces the desired results.

Among the industries that Wipro serves, the oil & gas sector is most closely parallel to the mining sector. Though mining companies pursue a much wider range of operation types and extract a wider variety of resources, they generally follow the same workflow processes as petroleum companies. Because of these similarities, Wipro’s deep experience in the oil & gas industry offers a significant business benefit to mining enterprises. We have tailored solutions that have proven successful in the oil and gas space to the specific needs and challenges of the mining sector. This gives mining companies access to reliable solutions that can ramp up quickly in their operations and that address key challenges in today’s market.

Yagya Swaroop leads the Environment Health and Safety Practice for the Energy, Utility and Natural Resources business unit at Wipro. His team of domain experts develops innovative solutions for environmental and corporate sustainability. He has successfully led numerous large programs in a global team environment and has delivered strategic corporate transformation projects for many companies around the globe. With over 17 years of top-tier consulting and industry experience, he has the unique ability to align broad corporate business needs with measurable goals for people, processes, operations, and information technology. Yagya’s qualification includes Electrical & Electronics Engineering and Management Program at IIM, Bangalore.

Sudip Chaudhuri leads the Mining Practice for the Energy, Utility and Natural Resources business unit at Wipro. With over 14 years of varied information technology experience across asset management and mining operations, Sudip has worked with numerous clients in the mining and minerals industry on transformational and advisory assignments. Sudip has deep domain experience across open cast and underground mining operations, mining supply chain, and mobility solutions applicable to the Mining sector. He had initiated ground-breaking innovations in mine safety for underground mines involving bundled voice and data communication and has a passion for energy conservation and safety practices in the mining context. During his career he has provided value to international mining giants and public sector mining organizations in North America, Australia, and India.