Introduction

The capital project construction phase and setup of operations is a key part of the life of a mine. While the exploration and validation of the resource is key to uncovering new value for mining companies, it is the capital project phase that requires huge investment to unlock this potential value. The value only starts to realize when production begins and product (first saleable grade ore) can be sold. This phase is very capital-intensive and costs need to be optimized.

Equipment purchasing, construction, labor and setup of physical plant and equipment consumes a large part of the budget. Digital needs of Information Technologies (IT) and Operational Technologies (OT) are sometimes deferred until later, sometimes right up to when operations are due to start. Systems are often installed in isolation and overall integration architecture delayed until revenue is available.

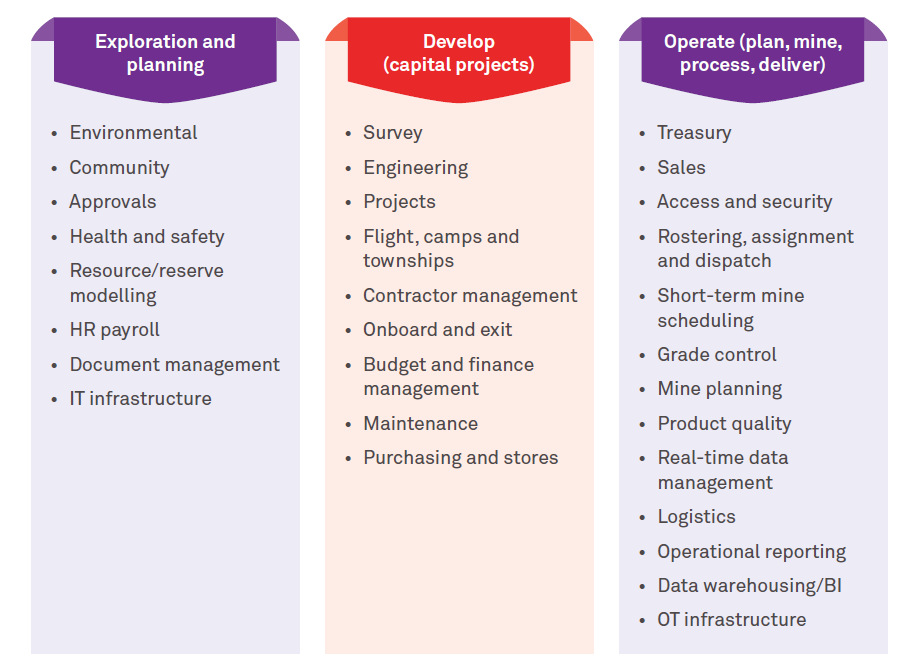

The IT and OT functional requirements are not all needed at the same time. Different functions are required early and others can be delayed until operations commence. Construction design and operating approach influence the IT/OT functional needs and the Systems and Applications that deliver these needs are part of the overall functional design.

Challenges for a capital project

There are a variety of challenges in determining the right mix of technology and when is the best time to deploy the Applications and Infrastructure. IT teams can support the business with the proposed methods of operation by defining the Business Process – this then identifies the complexity and scale to understand the suitability of the applications and requirements across OT and IT. So in essence, this phase is akin to building a house that will be stable in the long run (life of mine) where the design of not only the structure (the mine’s physical layout and processes) is needed but also the essentials like the electrical and piping and internal structures to go with it. The choices and variations of systems can be overwhelming and thus need a capital projects portfolio and assessment phase. Reference models in the industry that can align processes to applications for both OT and IT can help in getting this foundation right.

Approach for key business processes

One of the key decisions at this stage is the enterprise backbone that would integrate processes together with application and data. The design of this enterprise backbone is dependent on the following four pillars:

The digital core of most enterprise backbones is an ERP system. The approach to design an ERP varies in large and small organizations. A traditional enterprise architecture approach used by larger organizations would look at designing a set of toolkits that connect the four pillars (as mentioned above) as the ‘Operating Model’ for the company. The operating model and design would articulate processes and KPIs and connect with functions available in an ERP suite. The design and its further implementation is a very time-consuming and often long-drawn process (one year or more) that is also unaffordable when it comes to small and mid-tier miners.

To minimize complexity and optimize costs, a better approach for this segment would be to look for pre-configured solutions on the Cloud with minimal customizations that deliver a set of business processes, industry-standard security controls and preconfigured performance indicators. Ideally, these should come bundled with a set of mining best practices to cater to mining asset and cost structures, and commodity management that can be rapidly deployed within a few months on the Cloud or in multiple phases aligned with the capital project schedule. Opex models which include the technology platforms, license, and services bundled together, can provide cost optimization options.

Conclusion

The operating model for a capital project would be incomplete without the design of the digital foundation which then allows the transformation to a future digital mine. Getting the foundation right ensures the future ability of the organization to integrate data across the asset structure and optimize operations. The digital era has opened-up various economically feasible options on the Cloud with innovative pricing models. This is an exciting time for capital projects to establish a great digital foundation that can grow with the future needs of the mining business.

Sudip Chaudhuri

Global Practice Head - Mining, Wipro Limited.

Sudip Chaudhuri heads the Mining Practice for the Energy, Natural Resources and Utilities business unit at Wipro. With over 20 years of varied information technology experience in mining and mineral processing, Sudip has worked with numerous clients in the mining and minerals industry on transformational and advisory assignments, and designing end-to-end programs. With deep domain experience across the mining supply chain and execution, he has been able to effectively apply new technologies to bring about improvement in productivity and safety in the mining context.

He can be contacted on LinkedIn: https://www.linkedin.com/in/sudip-chaudhuri-3808bb11/?originalSubdomain=in

Email: sudip.chaudhuri@wipro.com

Joseph Plant

Natural Resources | Global Practice Lead – Operations Improvement, Wipro Limited.

Joseph leads Wipro’s global Operations Improvement Practice as part of the Natural Resources vertical and has experience in creating, designing and implementing operational improvement solutions for mining and metals customers.

Joseph has a background in industrial automation and software development. He has deep experience in operational systems such as MES (Manufacturing Execution Systems), and leading data science initiatives and analytics for operational systems.

Joseph has global experience and has worked on projects and opportunities across the globe including Australia, South Africa, China, Brazil, India, USA, UK, France, Belgium, Finland, Canada and Middle East.

Joseph can be contacted on LinkedIn: https://au.linkedin.com/in/josephplant

Email: joseph.plant@wipro.com