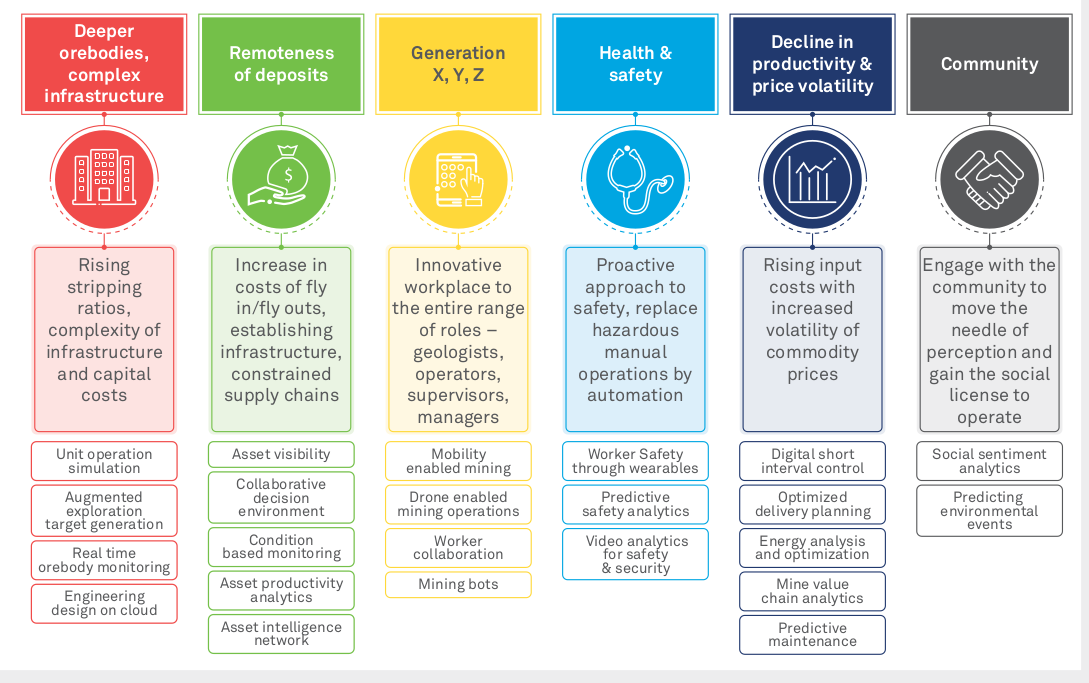

The impact of digital technologies and the underlying benefits to a mining business is now well established. However, applying the approach at the site of a mining operation where local management control exists requires a flexible and pragmatic approach. Most modern mines have implemented legacy systems (with proprietary intellectual property) that collect data, contextualize as well as provide a preliminary analysis from such data. Having said that, they fall short in managing end-to-end workflows, and as a result, have in-built inefficiencies. Every mine is unique in some aspects (a deeper ore body underground operation, remoteness of deposit, a next generation workforce, a complex outbound supply chain, a low-grade deposit, high labor cost, etc.) Therefore, there is no one-size-fits-all and any overarching digital mining framework needs to be tailored to the individual operation in question.

Approach to digital strategy

The following section provides an overview of key digital strategies that are relevant across a broad category of mining sites. The devil however, lies in the details and the context for a site. A few examples to illustrate the same are given below:

So, a carefully thought-out strategy with prioritization needs to be arrived at before embarking on a digital mission to transform the site operation.

Applying a digital mining framework to a mining site

Once the broad digital strategies are arrived at and understood, the next step is to undertake an assessment and review of the processes and applications that are currently being used for each mining function in the scope of the digital strategy. This is important to understand the investment that has already been made and if all areas are in focus. Identify how close the current applications and landscape fit with industry best practices for operational functions. This will review the key operational technologies at the mine to determine their existing use, their existing configurations and determine improvement projects and the technology roadmap they need to improve their operations and identify opportunities for cost reduction and increased productivity and safety.

Once this review is done, each digital strategy can be broken down into multiple use cases, with each having a journey of its own (often spanning multiple years) which can be programmed into a roadmap of digital projects to be delivered in an agile manner using a set of integrated platforms. It is likely that a combination of leveraging existing technology investments (enablers for digital) and modern digital technologies would be used with intermediate transitional approaches to usage of full blown integrated digital platforms

Few key considerations:

These are important guidelines to keep in mind while adopting a framework to a site operation:

Conclusion:

The benefits of a digital program in mining is well documented in the media. There is significant untapped potential for productivity improvement with a global average overall equipment effectiveness (OEE) performance of 27 percent for underground mining, 39 percent for open-pit mining, and 69 percent for crushing and grinding—compared with 88 percent for upstream oil and gas, 90 percent for steel, and 92 percent for oil refining. A 30 percent+ productivity benefits and cost reduction is not unachievable provided the hurdle of integration with existing technologies is overcome and risks of lack of knowledge to exploit new technologies is managed by the mining organization.

References:

How digital innovation can improve mining productivity.

Sudip Chaudhuri

Mining Practice, Wipro Limited.

Sudip Chaudhuri heads the mining practice in Wipro and leads a team of domain and technology professionals working in the areas of Mining Process Optimization. Over a period of 20 years, Sudip has had extensive experience in applying IT for Mining and Mineral Processing industries across roles of go to market, conceptualization, solution design, delivery of complex operations centric programs. In his role as a practitioner he has successfully led or mentored multiple projects for improving 4 asset utilization, operational efficiencies, driving insights from data, capital project portfolio strategies and embedding technology in operations for improving work practices that lead to top line growth and bottom line savings. In his current role he is responsible for advising clients on mining systems, creating innovative solutions and developing competencies that can provide the right technology enablement in a challenging industry environment.