July | 2020

Executive Summary

SCM market is poised for a double-digit growth for the next 6 to 8 years and Wipro has to capture this momentum to increase its share. With a combination of tech platforms, new age solutions, automation and consumer insights driven approach, this space will go through a rapid transformation.

In the current international business environment, heightened customer expectations impact every part of the supply chain. At the same time, next-generation delivery and logistics management solutions are making global supply chains smarter, faster, more customer centric, and sustainable.

Supply chain integration is an increasing focus for large companies. Wipro has good capabilities across domains and practices but is currently adopting a fragmented, reactive approach in tapping opportunities in this space.

There is a need to create an integrated SCM framework, deep diving into scope and breadth and building offerings catering to the holistic SCM landscape. This strategic view would require integration within Wipro to build and seamlessly reuse IPs, assets, platforms, use cases, solutions and competencies across verticals and Geos.

This paper provides a comprehensive view on the SCM market, Wipro’s capabilities and a strategic perspective towards Integrated Supply Chain Management.

Integrated Supply Chain Management – At a Glance

Integrated supply chain management refers to an enterprise resource planning approach to supply chain management. A business facilitates relationships with all of its suppliers and manages all distribution and logistics activities through a centralized system rather than having multiple systems within the organization.

Levels of Supply Chain Management

Strategic - deals with future planning than in looking at market evaluation, capacity issues, new products, and technology changes. This is accomplished at the executive management level.

Tactical - involves a shorter planning cycle. It is more concerned demand planning, inventory planning, and supply planning. This is determined at a less senior level than Strategic SCM.

Operational - deals with current planning activities measured in at most weeks. It includes demand fulfillment, scheduling, production, transport, and monitoring.

Benefits of Supply Chain Integration

Better understanding of customers and better ability to serve them, reduced wasted material & time and redundancy in supplier function, More Cost effective & efficient with increased ROI and profit margins, keep up with demand and be more flexible to changing markets, Less risk and enhanced competitiveness. Get early warnings for problems anywhere in supply chain due to information sharing, better opportunity for investment when operating with collective power

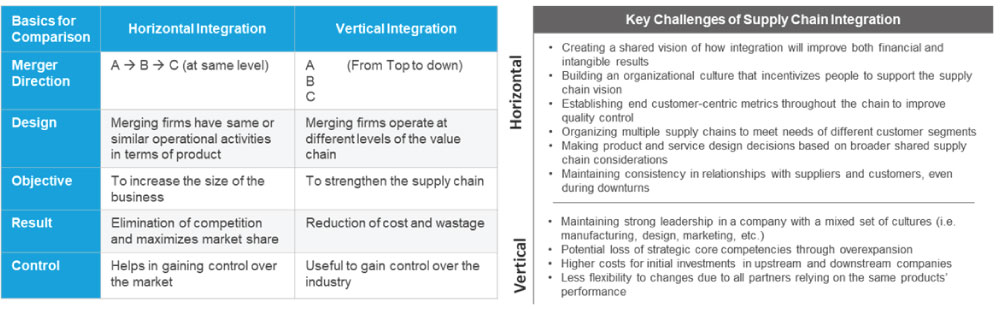

SCM Integration – Horizontal and Vertical

SCM as integration strategies aimed at coordinating functions across suppliers, manufacturers, distributors and retailers to ensure that products and services are produced and distributed at the right volume, location and time with the aim of reducing operational costs, maximizing profits and ensuring satisfaction across the supply chain. There are two types of SCM strategies:

a)Downstream/Forward Integration - A merger situation where the company acquires control over its distributors.

b)Upstream/Backward Integration - A merger situation when the company acquires control over its supplier.

Supply Chain Management – Best Practices

Key Supply Chain Best Practices

Some examples of Supply Chain Best Practices are:

Use of business intelligence and predictive insights driven partly by machine learning. Seamless integration of Supply Chain has enabled it to capture data on a real-time basis & simultaneously analyze data points and trends.

Scope and Breadth of Supply Chain Management

Supply Chain Management (SCM) Landscape

Control Tower

Control tower provides holistic management of supply chains. This includes management of revenue forecast, sales and operations, consumer demand & order, manufacturing, transport and logistics, warehouse, worldwide material sourcing and positioning. On the other hand, control tower also takes care of the collaborative response mechanism, cognitive computing engine and 360 degree visibility to the holistic supply chain operations. Control tower helps in self correcting, predictive and prescriptive decision support, early management of alerts and exception management, collaborative information sharing and end-to-end visibility. Various logistic processes play an important part in the overall supply chain management using control tower. All the logistic processes – inbound, outbound, intra-logistics, line feeding, logistic routing and warehouse management are covered using control tower management.

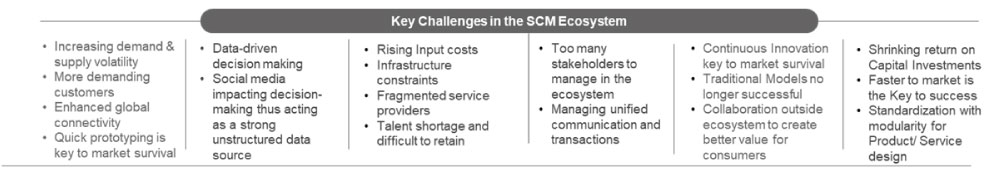

Key Challenges and Disruptions in Supply Chain

Key Disruptions and challenges posed by the current market trends are Globalization (Managing Complexity), Planning is Data driven (business need to invest in analytics tools), Ecosystem limitations (Geographical Barriers), Building Transparency (Unified Single Source of Truth), Innovation (Shorter Product Lifecycles) and Everything as a Service(Switch from a Capex to Opex Model)

Supply Chain Technology Trends

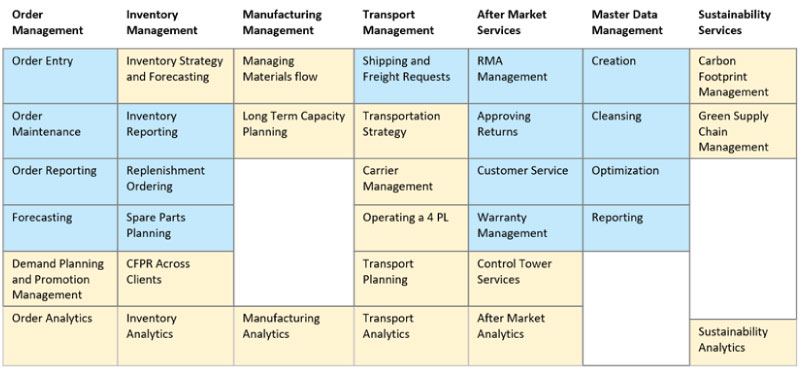

Maturity of SCM Segments – An Analysis

The above table shows the maturity of various SCM segments. The components in BLUE are highly mature and YELLOW are nascent as per the competitive market of service offerings and customer case studies from large number of service providers.

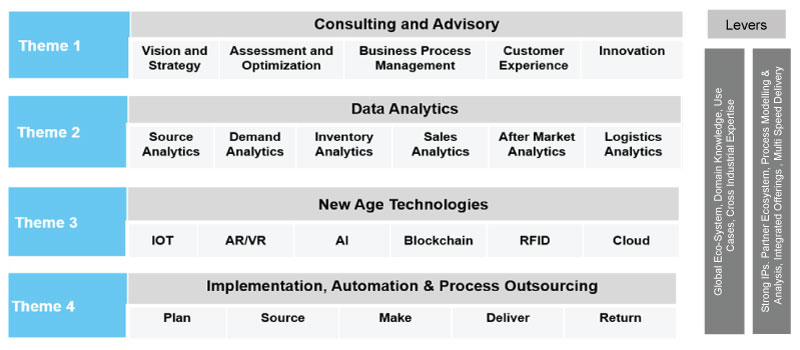

Integrated SCM Offerings – Theme Layer

References

Nikhil Goel

Consulting Partner – India,

Consulting Business, Wipro Limited

Nikhil Goel is a Consulting Partner Digital in the Global Consulting Business for Wipro. He has over 22 years of Consulting and Advisory experience across Public and Private Businesses. His areas of specialization include Digital Strategy, AI Strategy & Consulting, as well as Thought leadership, with an objective to transform business outcomes. He has authored several white papers and points of view on various topics covering Artificial Intelligence in effective Customer Personalization, Risk, Banking, Digital Supply Chain, and Warehouse Automation.

Nikhil can be reached at nikhil.goel3@wipro.com

Dr. Gurbinder Randhawa

Consulting Partner – India,

GCG, Wipro Limited

Gurbinder Randhawa is a Consulting Partner in the Consulting Business for Wipro, India. Gurbinder has over 18 years of Consulting and Management experience across Public and Enterprise verticals. Her areas of specialization include Cloud Consulting, Program Management, ERP Consulting, Cost Optimization, Thought leadership, Solution Theme Building, Practice, Business Development, and Revenue Generation.

She has written POVs on various topics covering Artificial Intelligence, Fraud Detection in GST, Trillion Dollar Economy, and Digital Economy.

Gurbinder can be reached at gurbinder.randhawa@wipro.com