Manufacturing Industry Cloud

Manufacturing Industry Cloud

Global manufacturing is poised for profound change. For the last century, the sector’s design, procurement, build, storage, distribution, and sales processes have remained essentially discrete, with individual technologies rarely developed to improve more than a single stage in the broader manufacturing value chain.

Manufacturing first movers, however, are now taking advantage of comprehensive, intelligent, cloud-based sensing and data analytics solutions to integrate and act on information from every step in the chain. Successful cloud integration solutions for the manufacturing sector are pulling data from across the enterprise into single, unified platforms that provide a real time view of any given process in the chain and can signal the consequences of any changes in the information they receive. They enable smarter and faster decision making, increased overall efficiencies and agility, and an improved ability to balance flexibility with resilience.

At the same time these platforms offer new opportunities for product and service innovation, including unprecedented customization, and for demonstrating regulatory compliance. Importantly, they speed process change itself and provide greater flexibility in the face of shifting customer demand.

Wipro Industry Cloud Overview

While the potential gains from integrated, cloud-based manufacturing are substantial, so are the challenges. Cross-unit integration is highly complex and requires significant investment. Effective process integration efforts extend beyond individual manufacturers to include upstream suppliers and downstream sales partners, requiring manufacturers to reframe their partner relationships and work within expanded and newly-dynamic production ecosystems.

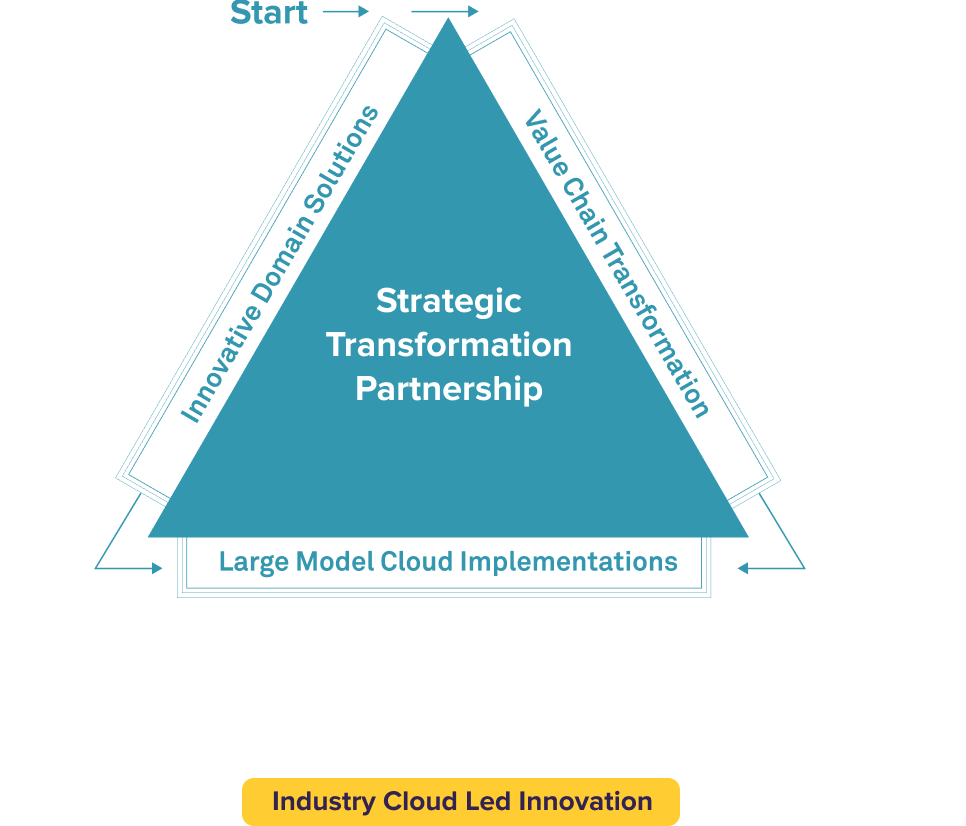

Wipro’s best-of-breed manufacturing cloud solutions help our customers design, build, and deploy integrated and intelligent processes that best meet their needs and deliver the efficiencies and agility they need, including the ability to thrive in the shifting ecosystems.

In partnering with Wipro on process integration, manufacturers are finding new opportunities for developing novel business models, new revenue streams, and new ways to connect with, and meet the demands of their customers.

Process in a Box Solution

Legacy manufacturing enterprises are typically built around geographically dispersed production facilities reliant on siloed systems and information flows that are slow to deliver actionable data at either the local or organizational level. This clearly impacts local control of facility costs, quality, and productivity, requires skilled personnel to be constantly fire-fighting, and affects both asset life and availability. Just as importantly, without a source of real-time information, timely corporate-level data analysis and decision making is impossible, placing enterprises at a major disadvantage to their more connected peers who are running modern, integrated digital manufacturing platforms.

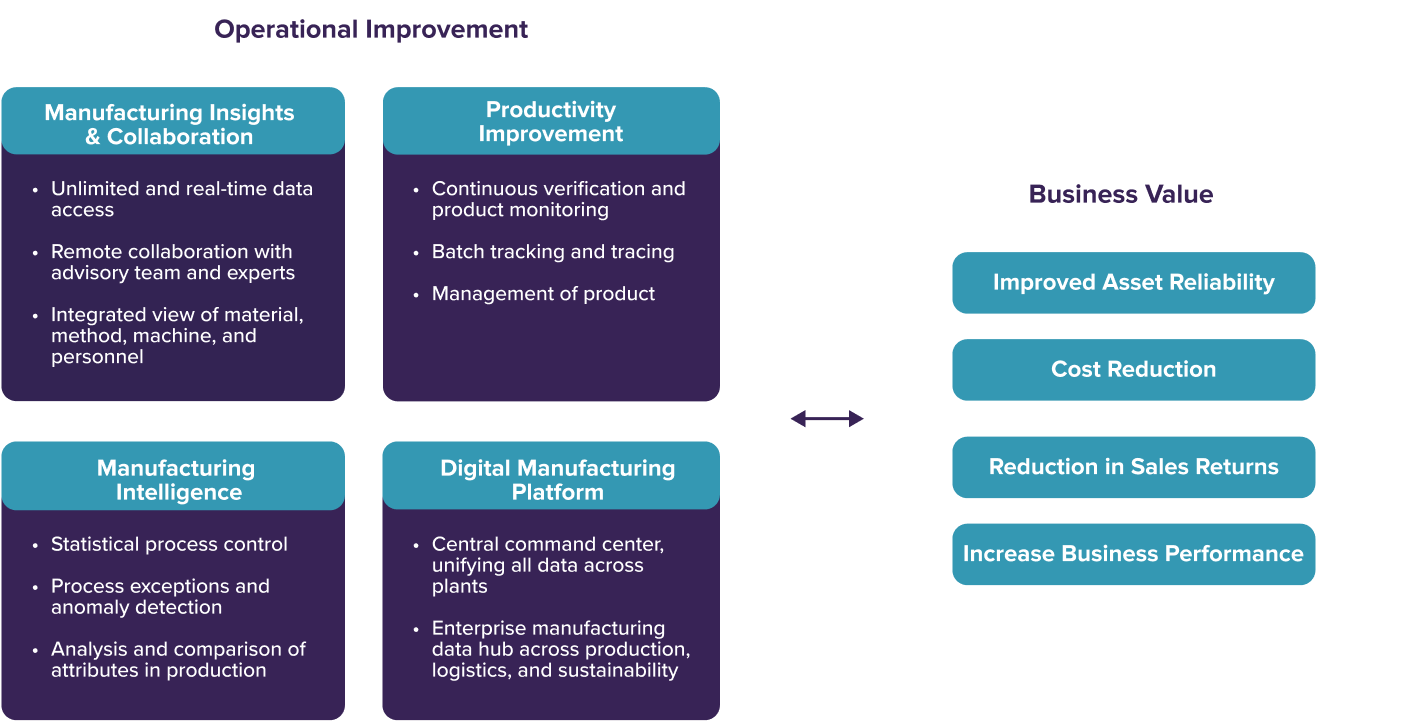

Wipro's Process in a Box (PIB) is a plug-and-play digital manufacturing accelerator that is helping manufacturers deliver a new level of visibility and operational excellence at both the individual facility level and across multiple plants. PIB gathers information outflows from across plant operations to create a single source of facility data, including in analytics, alarms, and reporting.

Accelerator Solution

Key Benefits for Wipro's Process in a Box

PIB enables real-time decision making and collaboration for both the individual plant and across the enterprise value chain. That includes flagging production and quality issues as soon as they occur, and adjusting outputs faster to meet anticipated demand.

PIB users are reporting significant improvements on key plant metrics including production quality and throughput, asset utilization, maintenance productivity, energy use, and sales return rates. At the same time, they are optimizing their overall supply chain management and building a foundation for future analytics solutions and new business models. Our customers, typically achieve a return on their PIB investment of between 1.5 and 2.5x within a year of going live.

Digital Logistics Solution

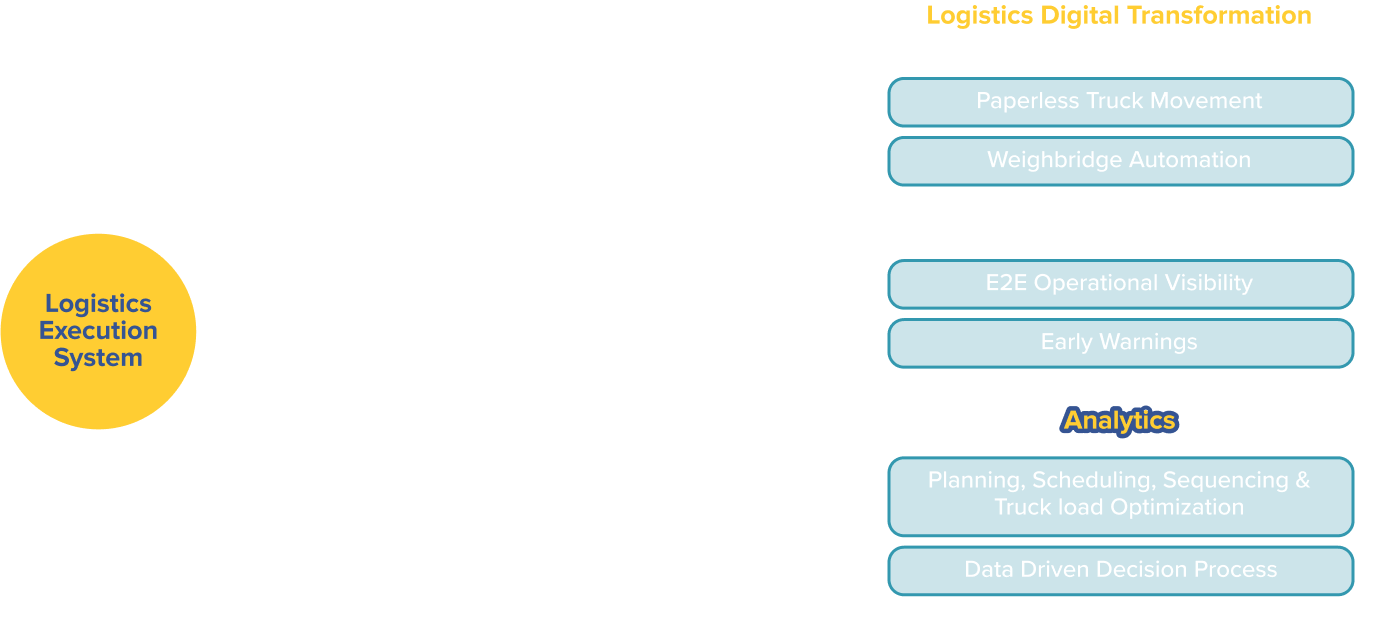

As manufacturers look to reduce inefficiencies and optimize supply chain management, they are under increased pressure to achieve true “just-in-time” in-bound and out-bound logistics. In-bound logistics requires tracking supplies as they arrive from multiple vendors, deciding where best to store them, and ensuring replacements are ordered in time to avoid manufacturing delays. On the outbound side, delivery trucks need to be optimally sequenced and directed as they move through the plant as well as optimally loaded and directed for delivery.

Wipro’s Digital Logistics Solution (DLS) is an execution system that provides an integrated, real-time view of both order sequencing/tracking and physical truck monitoring in a highly modular and scalable form. This includes the automated tracking of each stage in the process (passing security, parking, unloading/loading, weighing and exiting, etc.), and enables intelligent, demand-based management of supply chain allocation, scheduling, loading, inspection, and distribution.

Key Benefits for

Digital Logistics Solution

After implementing DLS, manufacturers are experiencing significant improvements in operational efficiency, including reduced truck wait times at the facility of 50% or more. They also report fewer production errors, improved anomaly reporting, more efficiently loaded delivery trucks, and a reduction in personnel required to manage the overall process.

Automated tracking provides comprehensive logistics data for real-time metrics reporting. The data can then be used as inputs for generating AI derived operational intelligence. Furthermore, a single version of logistics truth affords enterprise-level managers the ability to optimize cross-company logistics operations and quickly adjust when faced with shifts in the supply environment and changes in demand.

Why Wipro.

As manufacturers look to adopt cloud solutions that develop insights across their entire chains of production, Wipro FullStride Cloud is helping them adopt proven, secure, and scalable solutions like Wipro Process in a Box and Wipro Digital Logistics.

Wipro’s long-established and broad experience in the sector affords us a deep understanding of manufacturing value chains, an extensive network of best-in-class partners, and an unparalleled range of domain, sustainability, analytics, data platform, security, and cloud competencies upon which to draw.

Learn more about working with Wipro FullStride Cloud to embark on a future-facing transformation through powerful and cost-effective manufacturing industry cloud solutions.