The UK government has mandated that energy suppliers install smart metering systems across Great Britain by the end of 2024. Regulators estimate that energy suppliers will deploy 53 million smart meters during this period — a volume five to ten times higher than a supplier’s typical deployment numbers. To achieve this, suppliers will need to ensure high supply planning performance during the SMETS2 (second generation of smart meters) installation ramp-up. This paper explores how energy suppliers can succeed in this effort by bringing together all aspects of their end-to-end supply chain planning, such as demand or deployment, asset ordering and procurement, inventory management, and financial analysis.

Supply planning challenges

Managing asset procurement and logistics is one of the key challenges in supply planning. The reason: To scale up supply planning operations, energy suppliers need to forecast asset orders across asset types provided to the meter assets providers, manufacturers, and DCCs. At the same time, long lead times for order fulfillment, stocking challenges and policies, storage and delivery frequency limitations, likelihood of late delivery and orders, and the overutilization or underutilization of the warehouse or depot makes calculating the number of required assets difficult. Eliminating the threat of stock outages is, therefore, a significant operational challenge. These operational aspects translate into financial challenges, such as increased warehouse costs, asset rental costs, working capital utilization, and stock outage costs. Additionally, regulatory penalties, including GSOP (guaranteed standard of performance) liabilities awarded by OFGEM, need to be avoided by ensuring that the supply planning helps meet the targeted ramp-up smoothly.

An efficient and effective supply planning function that considers the entire breadth of supply chain operations is of paramount importance. (See Figure 1.)

Figure 1: Supply chain operations

Need for advanced analytics-driven supply planning

In the smart metering business, the supply chain drives a significant amount of costs for the suppliers. Despite this, 70% of business users still rely on spreadsheets1 and manual intervention for asset order forecasting. However, this approach is error-prone, expensive, and doesn’t support any scenario analysis or traceability. Therefore, innovative ways of supply chain planning are needed to minimize cost while achieving possible business benefits. No wonder companies in mature markets invest in asset data management and analytics platforms and capabilities as they generate value-added business insights for asset ordering and increase consolidation and collaboration to achieve end-to-end supply planning.

One of the key challenges with this approach is the availability of data with the right granularity. Leveraging advanced analytics in the supply planning function helps in calculating accurate asset order forecasts with the lowest granularity and aids in identifying policy requirements, realizing additional business benefits, and improving the overall efficiency of the asset-planning team. Additionally, strong scenario modelling capabilities or simulations can help the business understand the impact of deployment shifts (demand changes), inventory changes, non-delivery situations, and transportation inefficiencies on asset order forecasts in the run-up to ramp-up. Scenario modelling helps organizations make informed decisions by evaluating operational and financial impacts. Advanced analytics can, therefore, integrate supply chain planning functionalities, such as near real-time planning, by seamlessly bringing together deployment, supply, inventory, and finance, and continuous optimization. (See Figure 2.)

Figure 2: Supply chain planning functionality

Supply planning business objectives

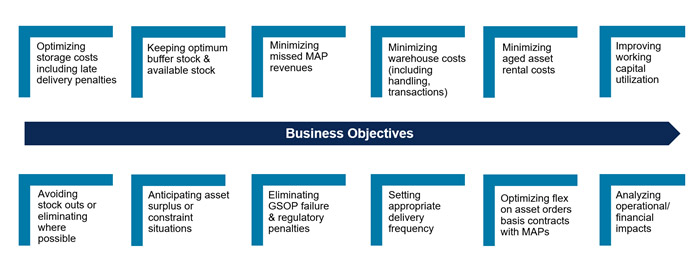

At a high-level, the objective of supply planning (see Figure 3) is to minimize cost, while ensuring regulatory compliance and avoiding GSOP failure, by producing highly accurate asset order forecasts at the lowest level of granularity. Expenses here can include different aspects, such as warehouse costs (including storage, handling, and transactions), aged asset rental costs, inventory costs, stock outages, and late delivery.

Figure 3: Supply planning business objectives

Solution Overview

Based on deployment profile or demand forecast, inventory information, and parameters such as stocking levels, contract lead times, non-delivery, transportation inefficiencies, and many more, an advanced analytics solution can generate optimized asset order forecasts for different asset types, fuel types, and MAPs. Advanced statistical analysis capabilities can provide business insights into key variables, such as delivery frequency, buffer stock, pallet size, order forecast flex, and late delivery. Optimization techniques can provide the supply plans by minimizing cost parameters while considering technical, operational, and financial constraints. For instance, while minimizing storage costs (including late delivery penalties), capacity plans and thresholds (related to workforce and logistics) can be considered possible input constraints.

Figure 4: Supply planning solution factors

Performing scenario modeling and what-if analysis as part of the planning process can provide businesses supply flexibility over frequently changing deployment plans (created due to shift to the right, sensitivity analysis), and inventory costs. Additionally, estimating the impact of changes in different parameters can inform policy decisions. Multiple scenarios can be compared for operational and financial impacts, and the baseline can be set after a cost-benefit analysis. Similarly, KPI reporting from the analytics platform with a consolidated data view can help identify the root causes for issues and assist with supply planning to generate business insights, visualize trends, and provide specific patterns. Alerts to internal and external stakeholders for certain cases, such as exceptions, late orders, and over- or under-used warehouses, can also be enabled. Thus, integrated supply chain planning functionality (e.g., near real-time planning) can enable unified planning across deployment, supply, inventory, and financial aspects.

Business benefits

Supply performance issues during deployment peak periods of smart meter deployment can be immensely costly. For instance, stock issues can hamper engineers from installing meters or taking customer appointments, resulting in missed MAP revenues and GSOP failure penalties. Warehouse cost also involves storage, handling, and transactions and is closely tied to buffer stock and delivery frequency. At the same time, the stocking principles applied in logistics operations drive aged asset rental costs. Advanced analytics can help reduce aged assets from 30% to 10% of the available stock, saving millions in cost over the course of a few years. It can also expedite tactical asset planning activities, thereby improving planning efficiency and sparing more time for strategic planning where advanced scenario modeling can drive value-added insights for deployment ambiguities.

Driving value through collaboration

By investing in advanced analytics and platforms, a business’ maturity in supply chain planning can evolve from a "siloed" or “reactive” state to a “collaborative” or "integrated” state by bringing together demand, supply, inventory, and financial aspects of planning on a single platform and driving further value through advanced analytics. Integrated supply planning can help businesses overcome operational and financial challenges while mitigating risks and driving cost savings in millions over the course of the deployment period and associated ramp-up of smart meter volumes. Furthermore, integrated supply planning can help make policy decisions and improve the overall efficiency of the asset-planning process.

References

Tarkik Patel

Principal Consultant, Decision Sciences practice, Wipro Limited.

Tarkik has over ten years of experience in Data Analytics and Artificial Intelligence. A management cum engineering graduate, he is immensely passionate about driving business value through advanced analytics and AI. He is well-established in leading advanced analytics & AI engagements for various customers across multiple industry sectors. A large chunk of his experience has been with utility customers across Europe and the US. In his current role, he is a Principal Consultant in the Decision Sciences practice at Wipro Limited.